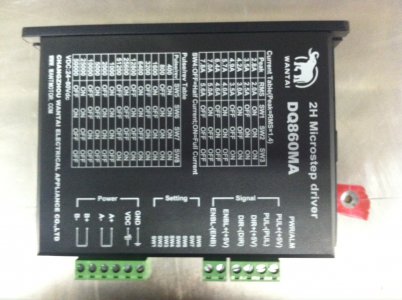

No, sorry. Those are 5V inputs from the breakout board. PUL is the pulse input, and DIR is the direction input. Normally you can connect the DIR- and PUL - to the GND terminal on the breakout board. Do not connect to the power supply.

The V+ V- connect to the +V and GND terminals on the drive, the ones right next to the motor connections.

OK. I think I've got it.

I need to run a wire from one of the power supply V+ terminals to the driver VDC terminal and another wire from one of the power supply V- to the driver GND terminal. Correct?

Tom S