-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Bend A 9" 3 1/2

- Thread starter Dragon

- Start date

- Joined

- Dec 19, 2014

- Messages

- 167

Thank you ARKnack , at less you makes me feel with some hope! and that was my first point before I got this lathe; is (learn) yesterday I took the apron and the gearbox in parts, and I will buy that rebuild kit from the ebay,

the only thing I need is to make sure my bed will get me a nice accurate cuts, my hobby required me to have a precision cuts and I just don't want to crash my expensive Helicopters with some runouts on their shafts!

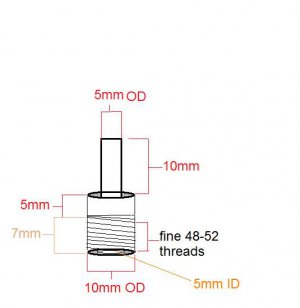

this is my first build using friend of mine lathewas fun and the shaft I had to make it was 10mm OD X 7mm ID with 6mm thread on bottom and the other end of the shaft is only 6mm OD solid and 7mm long

thank you!

There are a couple things I learned at different site. First thing to know is I am not a machist. Just a hobbiest. Your accuracy will depend on how long the shaft is. The longer it is the more tolerance required. Collets are very good along with a four jaw chuck. My understanding is the most accurate is between centers. Other will correct me if I am wrong. For straight shafting I would consider using drill rod.

- Joined

- Mar 4, 2015

- Messages

- 62

yes, to use the drill rod is a good option, however if I want to shave a shaft with different measurements, EX: my latest shaft I made was little complicated; the run out was .000 inside and .000 from outside. it took me about 3 hours to make it

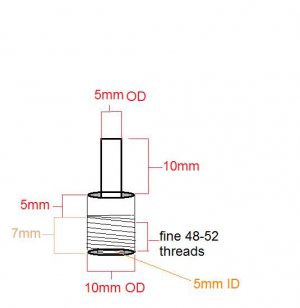

sometimes I do shafts 270mm long 10mm OD and that is the longer shafts I need to do, but it need to be hardened and .000 run out otherwise the main rotor for the helicopter will build crazy vibration ending up losing gyroscope electronic stabilization AND smash on the ground

I need some advises about some parts I found on ebay again (sorry about that, I know I been looking to get my lathe ready as soon as I can ),

),

I bought his tail stock and it's looks like in decent shape, and he already shipped out to me ($1oo plus $17 shipping )

so I called him and I asked him if he got the rest of the parts for that lathe, and yes! he got them all

so I started asking him to send me some pics of the Bed, lead screw, countershaft, spindle (since my spindle is been beating up from the front!) I am thinking to replace it too

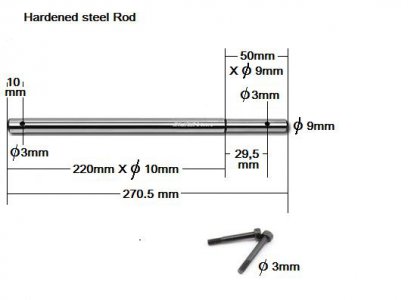

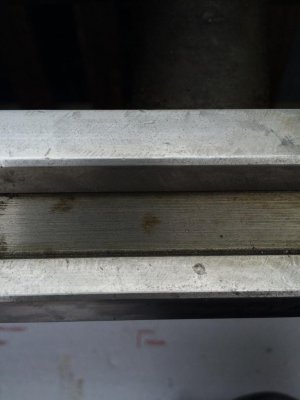

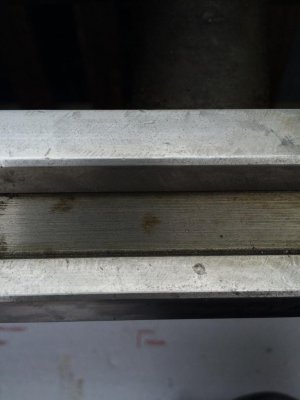

so he sent me these pics, he said these parts are for southbend 4 1/2 bed 9" B model he said ( I can't sale you the spindle itself instead he wants sale all headstock also the saddle I asked him for the handle and the bronze nuts but he said I will not be able to take it in parts instead he want to sale it all! also he confirm to me that this lathe is in great condition and the original SB motor is still there!!

he was very nice guy, He asked me to offer him some $$ number but I don't know how much I will pay for these parts IF they are good, he lives in NJ and he is welling to ship the parts one by one to save shipping cost, like the bed and the lead screw will be in different shipment, the headstock with different package Etc..

so I believe the B has same bed like A model, please correct me if I am wrong. I read somewhere that the south bend B has different bed that the A has! he said that the bed is in perfect condition.

thank you for all your inputs

sometimes I do shafts 270mm long 10mm OD and that is the longer shafts I need to do, but it need to be hardened and .000 run out otherwise the main rotor for the helicopter will build crazy vibration ending up losing gyroscope electronic stabilization AND smash on the ground

I need some advises about some parts I found on ebay again (sorry about that, I know I been looking to get my lathe ready as soon as I can

I bought his tail stock and it's looks like in decent shape, and he already shipped out to me ($1oo plus $17 shipping )

so I called him and I asked him if he got the rest of the parts for that lathe, and yes! he got them all

so I started asking him to send me some pics of the Bed, lead screw, countershaft, spindle (since my spindle is been beating up from the front!) I am thinking to replace it too

so he sent me these pics, he said these parts are for southbend 4 1/2 bed 9" B model he said ( I can't sale you the spindle itself instead he wants sale all headstock also the saddle I asked him for the handle and the bronze nuts but he said I will not be able to take it in parts instead he want to sale it all! also he confirm to me that this lathe is in great condition and the original SB motor is still there!!

he was very nice guy, He asked me to offer him some $$ number but I don't know how much I will pay for these parts IF they are good, he lives in NJ and he is welling to ship the parts one by one to save shipping cost, like the bed and the lead screw will be in different shipment, the headstock with different package Etc..

so I believe the B has same bed like A model, please correct me if I am wrong. I read somewhere that the south bend B has different bed that the A has! he said that the bed is in perfect condition.

thank you for all your inputs

- Joined

- Mar 4, 2015

- Messages

- 62

I just read somewhere else that the SB B, C parts will not fit on SB A also each Bed and way for each lathe is different than the other!!!

so if I try to use SB B bed or C bed with my SB A head stock and my saddle will need to grind the bed or the parts to get them fit together! they said just because when they made it back on the days they used different lots!

what a bad manufacturing if that is correct!

so if I try to use SB B bed or C bed with my SB A head stock and my saddle will need to grind the bed or the parts to get them fit together! they said just because when they made it back on the days they used different lots!

what a bad manufacturing if that is correct!

- Joined

- Oct 27, 2014

- Messages

- 272

Here's an example of a very nicely done 9"

http://www.practicalmachinist.com/v...-restored-9-model-south-bend-lathe-ks-267282/

When you're done with yours, it will likely look much like this with regard to the saddle and ways.

http://www.practicalmachinist.com/v...-restored-9-model-south-bend-lathe-ks-267282/

When you're done with yours, it will likely look much like this with regard to the saddle and ways.

- Joined

- Mar 4, 2015

- Messages

- 62

well, I been thinking to buy one of the grizzly's south bend 1001, BUT there is a errors on the bed and the spindle runout, that is what I read somewhere and I did call them, the costumer service are sooooooooooooooooo rude and he is the only one guy is answering the calls and he was sounds like don't like to work in this JOB!

so I gave up!! I just decided to buy the countershaft and the motor, since I got the tailstock then my lathe is complete!

also I found on my local craigslist a guy who want to sale his draw bar comes with 15 PC of 3c collet adapter and spindle protector, also SB milling attachment with 7 tailstock centers and one tailstock drill chuck with its handle, the 4 jaws chuck and the thread dial are not included and he is asking $600 for all that! I don't know if that a good deal or I am over paying!! he is waiting for me tomorrow to get him the money and get the parts!

so I gave up!! I just decided to buy the countershaft and the motor, since I got the tailstock then my lathe is complete!

also I found on my local craigslist a guy who want to sale his draw bar comes with 15 PC of 3c collet adapter and spindle protector, also SB milling attachment with 7 tailstock centers and one tailstock drill chuck with its handle, the 4 jaws chuck and the thread dial are not included and he is asking $600 for all that! I don't know if that a good deal or I am over paying!! he is waiting for me tomorrow to get him the money and get the parts!

- Joined

- Oct 27, 2014

- Messages

- 272

What is the "error in the bed"? All spindles have runout. How much runout is the question (a Sieg C6 is about 0.00016" and that's pretty good for a $1000 lathe). Some don't measure runout correctly (measuring a chuck runout is NOT the same).

If you are expecting 0.0000" runout on your lathe spindle, you're most likley barking up the wrong tree.

$600 seems to high to me. I first read your post as you are getting the countershaft and motor included in this. Is this correct? If it gets you the parts for a complete lathe then you're into it for $1100 so far? Expect to pay about $1000 to get the bed planed and scraped as well as the saddle fit to the bed and the cross slide and compound scraped. You could learn how to do the scraping and do this yourself, but it takes some practice and you will need more tools (not that that is a bad thing of course). It will be well worth it though and I am sure after all is said and done, you will have a very true bed and saddle that you are happy with.

Do you know if the motor in that countershaft functions? It looks like the wiring is pretty ratty.

You might be interested in one of these at some point. It is a casting for adding a T-slot cross slide to your lathe. It does require some milling. http://www.statecollegecentral.com/metallathe/S-4382.html

If you are expecting 0.0000" runout on your lathe spindle, you're most likley barking up the wrong tree.

$600 seems to high to me. I first read your post as you are getting the countershaft and motor included in this. Is this correct? If it gets you the parts for a complete lathe then you're into it for $1100 so far? Expect to pay about $1000 to get the bed planed and scraped as well as the saddle fit to the bed and the cross slide and compound scraped. You could learn how to do the scraping and do this yourself, but it takes some practice and you will need more tools (not that that is a bad thing of course). It will be well worth it though and I am sure after all is said and done, you will have a very true bed and saddle that you are happy with.

Do you know if the motor in that countershaft functions? It looks like the wiring is pretty ratty.

You might be interested in one of these at some point. It is a casting for adding a T-slot cross slide to your lathe. It does require some milling. http://www.statecollegecentral.com/metallathe/S-4382.html

- Joined

- Mar 4, 2015

- Messages

- 62

The last offer I got is to buy drawbar with it's collet 15 pc, collet adaptor, collet key, 7 centers, one live center, and milling attachment for $600

Since your guys recommend to go with collet setup!! Do you thing this is a good deal or I am overpaying here?

The eBay sounds very expensive when they sale these tools there!

So it mybe a good price!

Since your guys recommend to go with collet setup!! Do you thing this is a good deal or I am overpaying here?

The eBay sounds very expensive when they sale these tools there!

So it mybe a good price!