- Joined

- Mar 4, 2015

- Messages

- 62

HI,

I just bought an Old south bend Model A 3 1/2 from somebody bought it for some wood work and he didn't want it anymore, somebody told me I paid little high for it!

I paid $500 and the lathe is missing tail stock, thread dial, counter shaft, motor

it comes with old tool post and original south bend 3 jaw check!

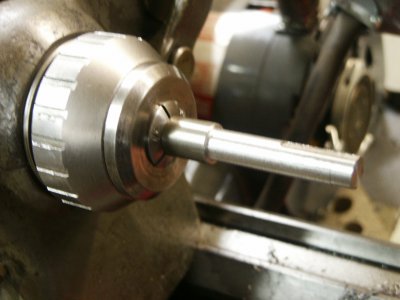

first I got it home I test the check with my dial (run out indicator) and show about .001 thousands of an inch) then I removed the check and test the spindle from the inside and from the outside was little space after the thread and the reading for both was 0.00 so there was no movement, the head stock is holding nice and tight!

then I took the saddle in parts to check the gears and all seems to be good!

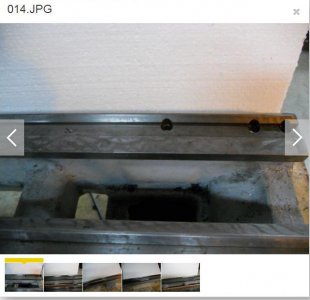

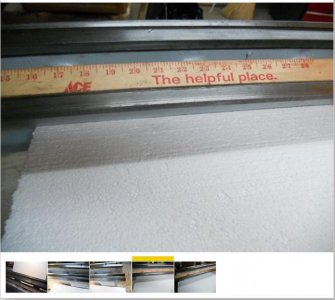

The BED and the way are fine but there are a lot of dent and heavy scratches near the head stock , don't know if that will effect the quality of the precision!

the Goal is to use this lathe for my RC helicopter parts fabrications, everybody may know that the Helicopter motors and the shafts run in High RPM's and any run out will cause a big vibrations and my could crash the model!

so I need almost 0.000 run out! it's may sound impossible to have that quality with these old lathes but I am trying to spend around $3000 total for getting what I want

now I need your guys advises about either keep it or sale it and get an another one!

I am very new to this and need your help please!

Thank you

I just bought an Old south bend Model A 3 1/2 from somebody bought it for some wood work and he didn't want it anymore, somebody told me I paid little high for it!

I paid $500 and the lathe is missing tail stock, thread dial, counter shaft, motor

it comes with old tool post and original south bend 3 jaw check!

first I got it home I test the check with my dial (run out indicator) and show about .001 thousands of an inch) then I removed the check and test the spindle from the inside and from the outside was little space after the thread and the reading for both was 0.00 so there was no movement, the head stock is holding nice and tight!

then I took the saddle in parts to check the gears and all seems to be good!

The BED and the way are fine but there are a lot of dent and heavy scratches near the head stock , don't know if that will effect the quality of the precision!

the Goal is to use this lathe for my RC helicopter parts fabrications, everybody may know that the Helicopter motors and the shafts run in High RPM's and any run out will cause a big vibrations and my could crash the model!

so I need almost 0.000 run out! it's may sound impossible to have that quality with these old lathes but I am trying to spend around $3000 total for getting what I want

now I need your guys advises about either keep it or sale it and get an another one!

I am very new to this and need your help please!

Thank you

, but again the seller refuse to ship!!! what a problem..

, but again the seller refuse to ship!!! what a problem..