- Joined

- Jan 10, 2012

- Messages

- 21

Steve,

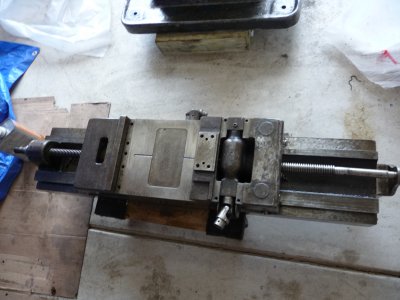

While I had my #12, 1952 vintage down to the same level of "strip"; I only found filler in the seam between the base

and column!

Here's the before picture: <https: picasaweb.google.com="" lh="" photo="" 0zxz1hfb7dck-stgv93gposc3tge6eogag5vhp7aegq?feat="directlink">https://picasaweb.google.com/lh/photo/0ZXZ1Hfb7DcK-Stgv93gPOsc3tGe6eOGAG5vHp7AEgQ?feat=directlink

Here's the after:</https:>

https://picasaweb.google.com/lh/photo/HX9h4OfO9y-t_JfY-8FNzOsc3tGe6eOGAG5vHp7AEgQ?feat=directlink

<https: picasaweb.google.com="" lh="" photo="" 0zxz1hfb7dck-stgv93gposc3tge6eogag5vhp7aegq?feat="directlink"><https: picasaweb.google.com="" lh="" photo="" hx9h4ofo9y-t_jfy-8fnzosc3tge6eogag5vhp7aegq?feat="directlink">

Since they perhaps came from the same pattern/sand mold/foundry, I suspect what you're seeing is a

reaction between the methchoride stripper and the original base coat of lead paint! Of course, YMMV; but

why would they "bondo" a brand new machine that had very few casting defects before paint?

I'd do a test with another M-C layer on a small spot and see if it re-dissolves it into a scrapeable layer of schmutz before

doing any "dry wheeling". And the dust is toxic, so cover up well if you decide to grind/needle/wheel it.

HTH.

--frankb

And I liked the color of the "raw" f-c coated cast iron I just threw a couple of coats of wax on it, and it remains

that finish to this day. Sort of "gun blue".

https://picasaweb.google.com/lh/photo/xZ2eKmzzb49W0_h5jwBl6esc3tGe6eOGAG5vHp7AEgQ?feat=directlink

Edit: Going back through my journal, I had a reaction between the ferric chloride converter and something; perhaps the soap I used to clean:https://picasaweb.google.com/lh/photo/R9z4s0ujyqdiWbK7Nqwht-sc3tGe6eOGAG5vHp7AEgQ?feat=directlink

</https:></https:>

SHOULD I take this down to bare metal? Or can I take advantage of the filler that is already in place and just fill (a little more), prime, and paint? Will my use of stripper cause issues with the paint adhering later on?

While I had my #12, 1952 vintage down to the same level of "strip"; I only found filler in the seam between the base

and column!

Here's the before picture: <https: picasaweb.google.com="" lh="" photo="" 0zxz1hfb7dck-stgv93gposc3tge6eogag5vhp7aegq?feat="directlink">https://picasaweb.google.com/lh/photo/0ZXZ1Hfb7DcK-Stgv93gPOsc3tGe6eOGAG5vHp7AEgQ?feat=directlink

Here's the after:</https:>

https://picasaweb.google.com/lh/photo/HX9h4OfO9y-t_JfY-8FNzOsc3tGe6eOGAG5vHp7AEgQ?feat=directlink

<https: picasaweb.google.com="" lh="" photo="" 0zxz1hfb7dck-stgv93gposc3tge6eogag5vhp7aegq?feat="directlink"><https: picasaweb.google.com="" lh="" photo="" hx9h4ofo9y-t_jfy-8fnzosc3tge6eogag5vhp7aegq?feat="directlink">

Since they perhaps came from the same pattern/sand mold/foundry, I suspect what you're seeing is a

reaction between the methchoride stripper and the original base coat of lead paint! Of course, YMMV; but

why would they "bondo" a brand new machine that had very few casting defects before paint?

I'd do a test with another M-C layer on a small spot and see if it re-dissolves it into a scrapeable layer of schmutz before

doing any "dry wheeling". And the dust is toxic, so cover up well if you decide to grind/needle/wheel it.

HTH.

--frankb

And I liked the color of the "raw" f-c coated cast iron I just threw a couple of coats of wax on it, and it remains

that finish to this day. Sort of "gun blue".

https://picasaweb.google.com/lh/photo/xZ2eKmzzb49W0_h5jwBl6esc3tGe6eOGAG5vHp7AEgQ?feat=directlink

Edit: Going back through my journal, I had a reaction between the ferric chloride converter and something; perhaps the soap I used to clean:https://picasaweb.google.com/lh/photo/R9z4s0ujyqdiWbK7Nqwht-sc3tGe6eOGAG5vHp7AEgQ?feat=directlink

</https:></https:>

Last edited: