- Joined

- Sep 22, 2010

- Messages

- 7,223

Posted with permission from Steve

Hello all-

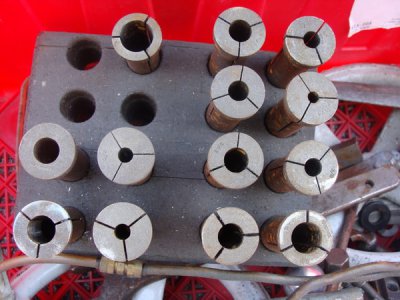

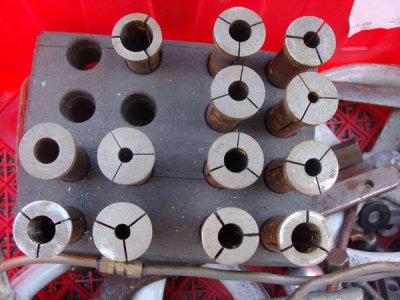

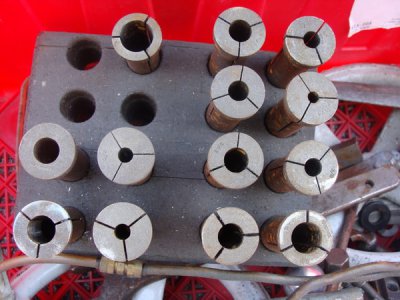

I'm creating this thread to chronicle my progress as I "refurbish" a Van Norman 12 milling machine. My plan at the outset is to scrape in the various sliding surfaces, but overall I just want a functioning machine tool with reasonable accuracy for a home shop. I acquired this mill a few days ago in less than stellar condition. It was given a terrible paint job of white (over a previous coat of safty blue) and the masking tape, etc. was still on the mill when i had it delivered. It looks to be in reasonable mechanical condition, as the spindle and gearbox seem to turn freely. I can't see any evidence of the mill being dropped, though there IS a portion of the leadscrew which has been brazed on; the far left of the x leadscrew has a threaded portion fitted on, I suspect it could have been done to accept a different handwheel since the PO had 3 original and one "different" handwheel on the machine. I also received a set of collets and an arbor, which are nice to have since these parts are hard to come by.

[h=2][/h]

[h=2][/h]

I'm creating this thread to chronicle my progress as I "refurbish" a Van Norman 12 milling machine. My plan at the outset is to scrape in the various sliding surfaces, but overall I just want a functioning machine tool with reasonable accuracy for a home shop. I acquired this mill a few days ago in less than stellar condition. It was given a terrible paint job of white (over a previous coat of safty blue) and the masking tape, etc. was still on the mill when i had it delivered. It looks to be in reasonable mechanical condition, as the spindle and gearbox seem to turn freely. I can't see any evidence of the mill being dropped, though there IS a portion of the leadscrew which has been brazed on; the far left of the x leadscrew has a threaded portion fitted on, I suspect it could have been done to accept a different handwheel since the PO had 3 original and one "different" handwheel on the machine. I also received a set of collets and an arbor, which are nice to have since these parts are hard to come by.

[h=2][/h]

[h=2][/h]