- Joined

- Feb 22, 2013

- Messages

- 159

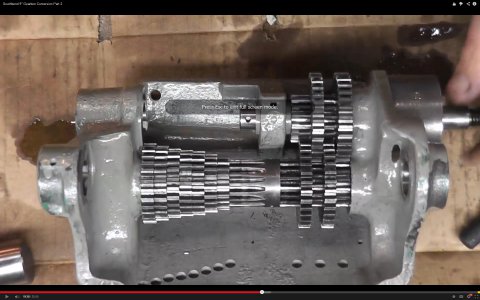

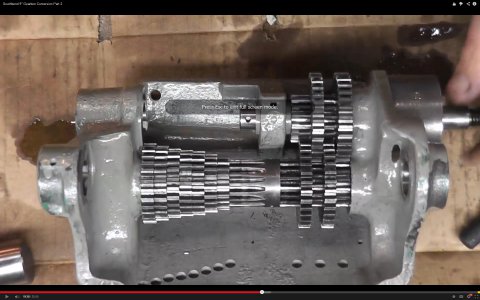

Are you sure it's the shaft with the gear tree? The gears next to the tree links with a set of gears on the small shaft with the collar. It may be the gear mesh here that's screwing you up. If you haven't already I would go shaft my shaft during disassembly and figure out if you are binding from the gears meshing together, the shafts in their respective bronze bushings, or the gears and bearings in the handle themselves. If you have everything out except that shaft with the tree of gears on it and you spin it and it still sticks you have a length or bushing issue. There are two gears that look almost identical. A large gear with a connected smaller diameter gear. If you look there are a couple of these, but look closely and you'll notice on some of them the smaller diameter gear is thinner. Another one has a thicker large diameter gear and a thinner small diameter gear I suspect you have these in the wrong place.

It should look like this:

It should look like this: