-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sb Fourteen Project???

- Thread starter Kroll

- Start date

- Joined

- Nov 14, 2014

- Messages

- 851

Kroll, did you by chance take apart the pulleymsystem to change the belt? Iam wondering what is the best way to do that?? I need to change the belt on my new to me Fourteen, and have read the spring tension on the pully is a bear to deal with.

Thanks

Glenn

Thanks

Glenn

Glenn if mine is the same as yours (reeves pulley) I screw out or open up the reeves pulley until belt was completely loose.Then I was able to take the belt off so that I could clean the inside of the upper/lower pulley.But maybe I was able to get it off cause I had the whole cradle out and the transmission was unbolted,can't remember

- Joined

- Nov 14, 2014

- Messages

- 851

Thanks Kroll, there is very little other SB Fourteeninfo floating around the internet about repairing these machines, so, your story here is quite valuable for explaining how to tear these machines down.

As a post script to your rebuild, i thought I might add a couple of bits of information I learned from tearing my Fourteen down and putting it back together. It's very similar vintage to yours.

- regarding the V belt that drives the Variable speed "Reeves Type" pulley system. It is not actually a Reeves drive, but does function the same way - the top pulley , on the transmission, has a large, heavy coil spring in the pulley housing that forces the pulley closed as the bottom pulley opens and closes. When changing the belt, one should be careful not to unbolt, or loosen the top pulley . the spring will throw parts out all over, and be very difficult to compress back into place. Just leave it alone and open the pulley system to its slowest speed with the drive motor. Then slip the old belt off the lower drive pulley , then take it off the driven pulley on top. Use a 1" flat bar to gently force open the top pulley to reinstall the new belt.

Second thing I learned, - the drive pulley on the bottom is driven by a small motor that turns a stud gear. A small 'counter' device (1"diameter, round blue component in the picture below) connected to the end of the little plastic drive chain, turns 10 times then locks up at the end of its run.

(Edit: this device is called a three terminal potentiometer...)

It is NOT actually a free turning component -it is made with some kind of internal gear or stop that halts its spinning motion at 10 rotations - just enuf to measure the travel of the pulley pulley back and forth to its fullest, and then most minimum extent. So 10 rotations each direction, then stop.

I mention this in detail because IF one takes the pulley assembly out of the frame, and removes the lower unit drive mechanism. This will cause the alignment of the potentiometer to be lost. Resulting in 'over Reving' the little 'Pot' upon reassembly and either breaking teeth off the gear, or spinning the device on its shaft and so breaking the 110v wiring connections off the attachment points. (Ahaha, I've done this twice so far - broke the wires and lost two teeth- until I discovered the rotation thing)

The key upon reassembly is to spin The pot to the full end of its travel, and install in the full open (slowest lathe RPM) pulley position. This will allow the pot to rotate a full 10 revolutions on its shaft, as you increase the speed of the lathe - opening and closing completely with out breaking anything.

The SB Fourteen operator's manual warns about not changing the setting of this drive chain and gear, as "damage may result". But the manual doesn't say what damage might occur, or how to reset the drive gear. I believe, the above description regarding setting the defice limit to the end of its 10 revolutions will prevent such damage.

Well, that's what I've learned so far... hopefully this will,benefit someone else who may take on a SB Fourteen project in the future.

Regards

Glenn

As a post script to your rebuild, i thought I might add a couple of bits of information I learned from tearing my Fourteen down and putting it back together. It's very similar vintage to yours.

- regarding the V belt that drives the Variable speed "Reeves Type" pulley system. It is not actually a Reeves drive, but does function the same way - the top pulley , on the transmission, has a large, heavy coil spring in the pulley housing that forces the pulley closed as the bottom pulley opens and closes. When changing the belt, one should be careful not to unbolt, or loosen the top pulley . the spring will throw parts out all over, and be very difficult to compress back into place. Just leave it alone and open the pulley system to its slowest speed with the drive motor. Then slip the old belt off the lower drive pulley , then take it off the driven pulley on top. Use a 1" flat bar to gently force open the top pulley to reinstall the new belt.

Second thing I learned, - the drive pulley on the bottom is driven by a small motor that turns a stud gear. A small 'counter' device (1"diameter, round blue component in the picture below) connected to the end of the little plastic drive chain, turns 10 times then locks up at the end of its run.

(Edit: this device is called a three terminal potentiometer...)

It is NOT actually a free turning component -it is made with some kind of internal gear or stop that halts its spinning motion at 10 rotations - just enuf to measure the travel of the pulley pulley back and forth to its fullest, and then most minimum extent. So 10 rotations each direction, then stop.

I mention this in detail because IF one takes the pulley assembly out of the frame, and removes the lower unit drive mechanism. This will cause the alignment of the potentiometer to be lost. Resulting in 'over Reving' the little 'Pot' upon reassembly and either breaking teeth off the gear, or spinning the device on its shaft and so breaking the 110v wiring connections off the attachment points. (Ahaha, I've done this twice so far - broke the wires and lost two teeth- until I discovered the rotation thing)

The key upon reassembly is to spin The pot to the full end of its travel, and install in the full open (slowest lathe RPM) pulley position. This will allow the pot to rotate a full 10 revolutions on its shaft, as you increase the speed of the lathe - opening and closing completely with out breaking anything.

The SB Fourteen operator's manual warns about not changing the setting of this drive chain and gear, as "damage may result". But the manual doesn't say what damage might occur, or how to reset the drive gear. I believe, the above description regarding setting the defice limit to the end of its 10 revolutions will prevent such damage.

Well, that's what I've learned so far... hopefully this will,benefit someone else who may take on a SB Fourteen project in the future.

Regards

Glenn

Last edited:

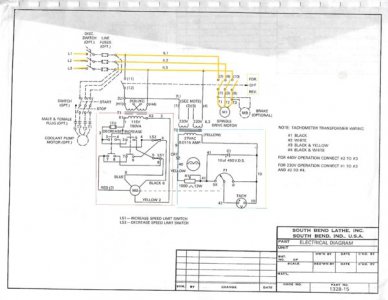

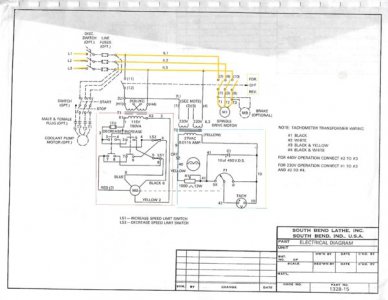

Thanks Glenn,I did not know that.Sometimes in this lathes life I guess that motor went out and someone change it over to where the operator would have to manually change rpms by turning the knob that they locate on the lower half of the cabinet.I wish that all the original parts for speed control was there but its not,so its one of those as/is lathes.I don't know if you have a wiring diagram but this was pass down to me so maybe it will be helpful to other members like the info that you had posted about the reeves drive motor.(I would have been one that would have mess it all up )

)

- Joined

- Nov 14, 2014

- Messages

- 851

kroll, that is exactly the little device and gear that I wrote about. The gear you show is a 60 tooth 3" gear, maybe a 31/2" OD gear on my lathe. This gear drives the gear on the pulley, and a smaller plastic stud gear mounts on the motor and drives this gear.

Your electrical diagram looks very similar to the one I have...

Glenn

Your electrical diagram looks very similar to the one I have...

Glenn

Last edited:

- Joined

- Nov 14, 2014

- Messages

- 851

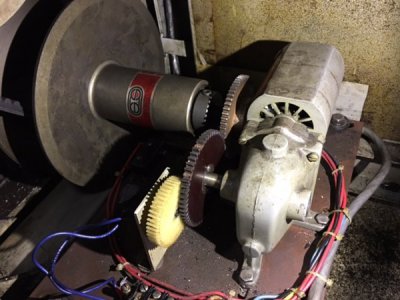

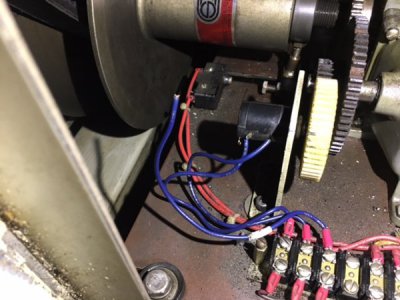

Took a couple of pics of the variable speed pulley system and the little plastic drive train that opens and closes the lower pulley. Look for my twice broken blue wire. They took pity on me the second time I brought it in for repair and said "No charge"! Customer for life now.

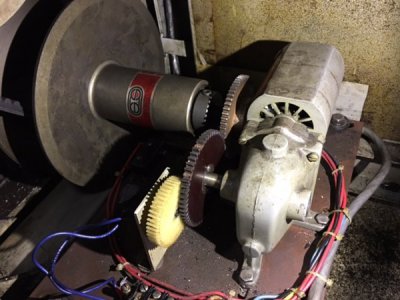

For FYI, Here are the photos relating to the variable speed pulley system adjustment in the above posts:

First photo shows the configuration of the variable speed motor and drive chain that opens and closes the lower pulley. The yellowish-white plastic gear on the end drives the potentiometer, thus sending a voltage measurement representing spindle speed to the RPM meter on top of the lathe.

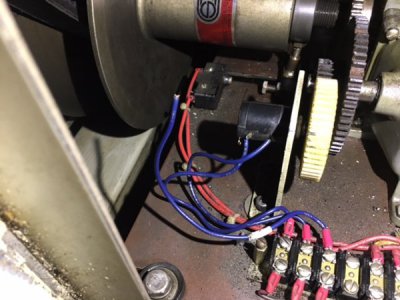

This small round pot with three blue wires is the device that has a 10 revolution limit. If not installed correctly, the large motor just off camera to the right, will force this small device to rotate on its shaft and wrap the wires till they break off the soldered joints. Also the finer gear teeth can strip out - as shown on the brownish gear. The broken blue wire in the photo leads up to the RPM gauge on top of the headstock.

Glenn

For FYI, Here are the photos relating to the variable speed pulley system adjustment in the above posts:

First photo shows the configuration of the variable speed motor and drive chain that opens and closes the lower pulley. The yellowish-white plastic gear on the end drives the potentiometer, thus sending a voltage measurement representing spindle speed to the RPM meter on top of the lathe.

This small round pot with three blue wires is the device that has a 10 revolution limit. If not installed correctly, the large motor just off camera to the right, will force this small device to rotate on its shaft and wrap the wires till they break off the soldered joints. Also the finer gear teeth can strip out - as shown on the brownish gear. The broken blue wire in the photo leads up to the RPM gauge on top of the headstock.

Glenn

Last edited: