-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SB 9A Cabinet underdrive lathe

- Thread starter ottrunner

- Start date

- Joined

- Mar 21, 2018

- Messages

- 1,600

I purchased the larger size that would hold the complete QCGB casting in total submersion. Worked like a charm.

Also made removal of 6 layers of various color paint from the headstock cover as well.

Peeled right off like it was an orange!

How big is and where did you get your ultrasonic cleaner? How much did you pay?

Weekend progress.

I thought I'd have a go at the headstock. Seeing as I have 2 of them I thought I would disassemble them both, cleaning up the original first.

The original headstock has modifications for coolant, a shield on the back, and slots for the brass block off plates on the bed.

It shows a bit of wear but I'll clean it out, put in new felts and offer it for sale on ebay with lots of photos. It might be a nice part for someone looking to make a bench lathe work as an underdrive.

The rear shield

The slots, factory cut or after?

Oil drain passages cleaned out. Some marks on bearing but nothing to catch a nail on, lots of life left in it!

That's it for today.

I thought I'd have a go at the headstock. Seeing as I have 2 of them I thought I would disassemble them both, cleaning up the original first.

The original headstock has modifications for coolant, a shield on the back, and slots for the brass block off plates on the bed.

It shows a bit of wear but I'll clean it out, put in new felts and offer it for sale on ebay with lots of photos. It might be a nice part for someone looking to make a bench lathe work as an underdrive.

The rear shield

The slots, factory cut or after?

Oil drain passages cleaned out. Some marks on bearing but nothing to catch a nail on, lots of life left in it!

That's it for today.

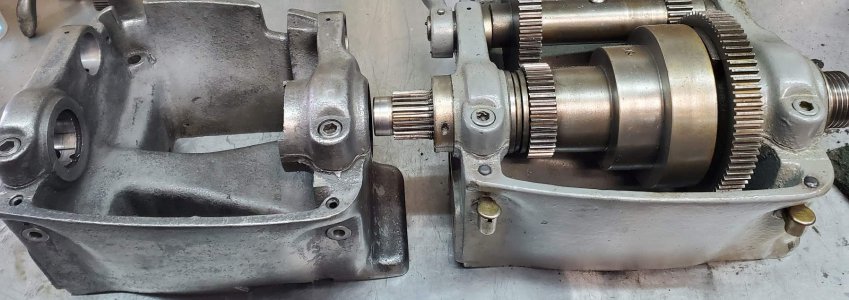

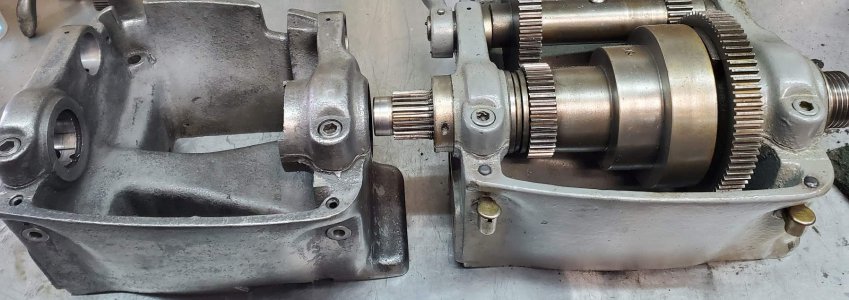

Although the new headstock appeared to be in excellent condition I thought it best to disassemble and inspect.

The bearing surface on it is perfect although it doesn't have the "high speed" grooves.

The spindle wicks were replaced with horizontal type rather than the underdrive spec ones. The proper rebuild kit is on the way, stuck in USPS limbo.

I will complete disassembly and repaint and hopefully, the new felts will be here. I also ordered the needle bearings to perform that upgrade.

It's also missing the surface tension breakers for the oil return, I will take them from the original headstock.

The bearing surface on it is perfect although it doesn't have the "high speed" grooves.

The spindle wicks were replaced with horizontal type rather than the underdrive spec ones. The proper rebuild kit is on the way, stuck in USPS limbo.

I will complete disassembly and repaint and hopefully, the new felts will be here. I also ordered the needle bearings to perform that upgrade.

It's also missing the surface tension breakers for the oil return, I will take them from the original headstock.

16 balmy degrees here today so I wheeled the cabinet, it's on leveling castors now, they raise the lathe 3 inches and a tall man needs that extra height to prevent back pain. Went over it with a wire wheel on the grinder. It will need another session of that to go over what I missed.

Plan is to paint the cabinet the same color as the lathe but keep the lip and interior of the chip pan natural. Maybe sand it to 320, or even 600 for a bit of sparkle.

Pics on that in a week when it's warm enough once again for a second round. The garage is like a bomb went off inside an 80-year-old lathe cabinet, lathe parts everywhere.

Plan is to paint the cabinet the same color as the lathe but keep the lip and interior of the chip pan natural. Maybe sand it to 320, or even 600 for a bit of sparkle.

Pics on that in a week when it's warm enough once again for a second round. The garage is like a bomb went off inside an 80-year-old lathe cabinet, lathe parts everywhere.

Last edited:

Sunny days, just trying to get things in order. I was about to throw out the coolant system, it is a cast iron tub and weighs a ton but while dragging it out to the curb for the scrapper I noticed this:

It's an actual south bend part! I guess that means a paint job and reinstallation.

Now that I have done away with the 550v motor that was on the lathe I'm considering using a treadmill motor, I have one, thoughts?

It's an actual south bend part! I guess that means a paint job and reinstallation.

Now that I have done away with the 550v motor that was on the lathe I'm considering using a treadmill motor, I have one, thoughts?

- Joined

- Sep 28, 2013

- Messages

- 4,318

treadmill motors are great, I'm working up a mount and drive for my SB9 right now. A 2hp (real, not TM duty) motor would be a good fit for a SB9 as that'll leave you plenty of power with the speed turned way down. Make sure you gear/ pulley the motor down - they run over twice as fast at full speed than a regular 1750rpm motor. Mine has a 4:1 reduction from motor>countershaft, then 1.5/0.8/0.5 (I'd have to check) ratios from countershaft>spindle.

Do you have a thread on the go so that I can see your progress?treadmill motors are great, I'm working up a mount and drive for my SB9 right now. A 2hp (real, not TM duty) motor would be a good fit for a SB9 as that'll leave you plenty of power with the speed turned way down. Make sure you gear/ pulley the motor down - they run over twice as fast at full speed than a regular 1750rpm motor. Mine has a 4:1 reduction from motor>countershaft, then 1.5/0.8/0.5 (I'd have to check) ratios from countershaft>spindle.

- Joined

- Jan 2, 2014

- Messages

- 8,854

Do you have a thread on the go so that I can see your progress?

I believe this is the thread (now on its 6th page):

https://www.hobby-machinist.com/thr...-silent-drive-casting-trade.87737/post-837781

-brino