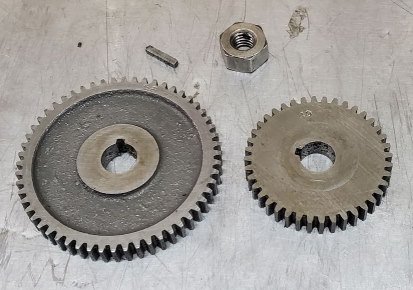

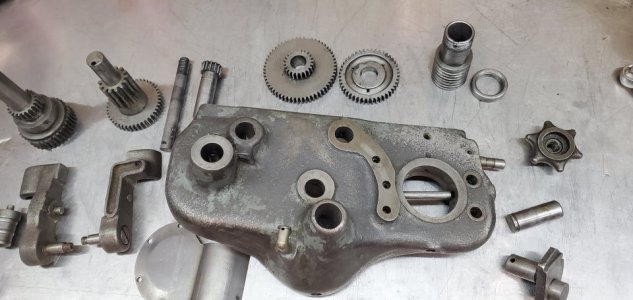

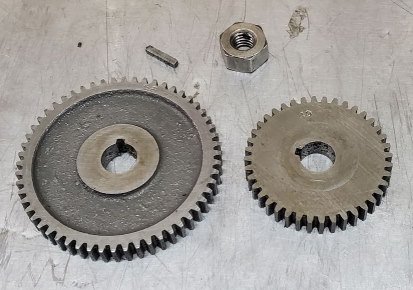

More scrubbing. I had already worked the cross slide and the taper attachment but went at them and a few gears the other day. I long for the day I can touch any of this without gloves.

I also ordered a gallon of Rust-Oleum V7400 high gloss in Navy Grey. I had considered doing the cabinet and lathe in different shades of grey but may do both in this. I plan on adding a hardener also.

The lathe has seen a coat of paint along the way, it seems like it was originally a medium to dark grey and somewhere along the link someone opted for a lighter grey with a blue/green tint.

Jury is still out on the 2 tone vs single at the moment...viewing these photos has left me undecided.

Some photos:

I also ordered a gallon of Rust-Oleum V7400 high gloss in Navy Grey. I had considered doing the cabinet and lathe in different shades of grey but may do both in this. I plan on adding a hardener also.

The lathe has seen a coat of paint along the way, it seems like it was originally a medium to dark grey and somewhere along the link someone opted for a lighter grey with a blue/green tint.

Jury is still out on the 2 tone vs single at the moment...viewing these photos has left me undecided.

Some photos: