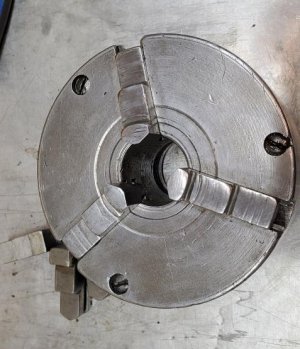

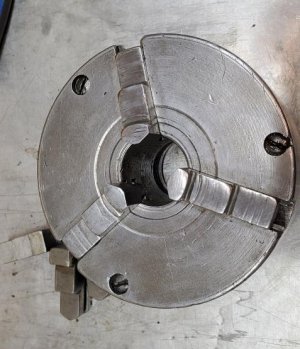

Tonight I thought I might have a go at the chucks. Before and after of the 3 jaw which appears to be a cushman and the 4 jaw which I'm not finished with, a skinner.

Also, the headstock I received with the lathe.

I hope you don't mind me sharing my experience in this image-heavy thread. It's a pleasure for me to do the work and while I search for information I find myself reading other threads and hope mine might someday offer some assistance.

Also, the headstock I received with the lathe.

I hope you don't mind me sharing my experience in this image-heavy thread. It's a pleasure for me to do the work and while I search for information I find myself reading other threads and hope mine might someday offer some assistance.