Great looking saw. I just finished restoring and setting up its little brother, a '52 14" 40B. After being unhappy with a later model Delta turret and left a little bored with a DeWalt 7790 I hope that this will be the saw I keep for the next 30 years. Took about a year of watching to find it. It was not well used but also not real well cared for. Took a lot of cleaning up but there's hardly any wear.

I ripped on my RAS's quite a bit in the beginning (and even plowed some with a dado) since my first "table saw" was a Shopsmith and not always set up for ripping. Set up properly it's not as exciting as most people make it seem.

On the topic of the thread, I bought a 3hp PCS to replace my Shopsmith about a year ago and have been really happy with it. I'm a hobbyist (no rush) and careful with setups so I never expected to use the brake and haven't yet, but the price difference is small enough to comparable saws that it is cheap insurance.

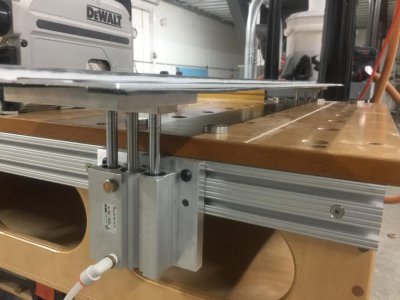

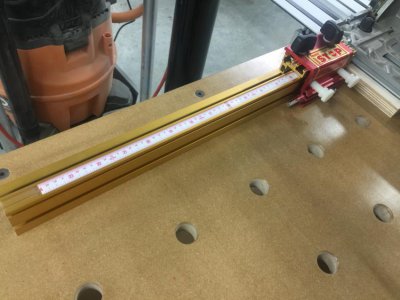

The only issue I've run across is that they use some soft fasteners to secure the front rail and I stripped one out and messed up the threads on the rail when I was adding a router table to the extension. They offered to send a whole new rail out for me no charge but I just drilled and tapped it for the next size up and was more careful. Also thought it was weird that a safety-centric saw would ship without a Euro style fence when almost all their competitors have it. I'll probably swap a unifence to it someday.