-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rockwell serial number?

- Thread starter astjp2

- Start date

- Joined

- Oct 7, 2013

- Messages

- 305

Hope this one works out for you. I still haven't taken any measurements on my bed. It doesn't appear to be badly worn to the eye, but you can never tell for sure without measuring, I guess. On the other hand, the ways on the saddle have quite a bit of wear. I have also noted a bit of wear on the ways of the tailstock. Haven't decided what to do about that yet.

- Joined

- Aug 23, 2013

- Messages

- 970

Well I finally got my new bed from Joe at Plaza, I did some measuring, just preliminary but it looks like there is only about .0005 on the flat ways for wear and the inverted V was only about .001", my old one was worn almost .010 on the inverted V's and the flat way was .0035. I still have some more cleaning of the anti corrosion and some paint drops off, but I am much happier with spending 600 for the new bed and lead screw. Now I have to find some paint, start disassembling the cabinet, sandblast and reassemble. I am also going to pull the motor and have new bearings, brushes and start capacitor put in. I am also looking at getting a test bar for the head and tailstocks, they are REALLY expensive but it will ensure that I am within .0005 in a foot for headstock alignment...... It will probably take all summer but I think I now have a keeper. Tim

- Joined

- Aug 23, 2013

- Messages

- 970

Well I think I found a tail stock turret and a milling attachment. The guy with the milling attachment is asking 400, I think that is too much so I only offered 300. It looks rough but I think I can make it useable. The turret attachment is 300, but I am not sure if its off of a Rockwell or not, I need to find some measurements to compare it to or at leas see if it fits the ways. Tim

- Joined

- Aug 23, 2013

- Messages

- 970

I went out to the shop and scraped the weird few drops of what looked like yellow paint and some gray overspray off and did some good measuring, it has a little wear but I found .0014 on the thickness of the rear way where the saddle gib wears, and there is less than .001 from what I can measure on the front inverted v way. Once its on the table is mounted and the bed is leveled, I think I will get a better feel for the alignment. Right now its sitting on my surface plate and rocks back and forth some, the surface plate is not quite long enough for me to get the leveler feet down and the table sitting flat. I finished measuring and wiped some way oil on the ways and called it a night. I am glad I built the tools to measure the ways and got the surface plate. Bebop was very helpful in verifying my surface plate and I am comfortable that I am measuring things correctly. Tim

- Joined

- Aug 23, 2013

- Messages

- 970

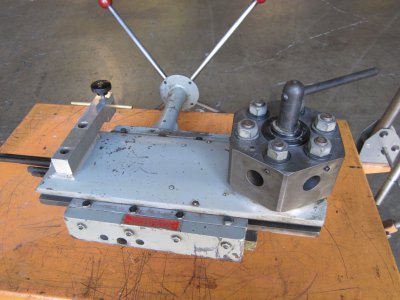

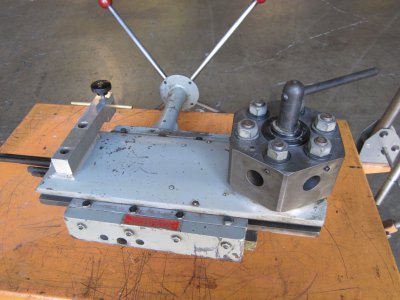

I added a new feature to my lathe, now I just need to decide if it is going to fit....What sayeth the tribe? This thing is real cool, it advances the indexing when you retract it fully and then you can set the depth with the set screws on the right side. I am not sure if this had the right height yet, if not, I will be looking to pass it on to the next person. I wonder what lathe has similar width ways but taller inverted V...

Tim

Tim

- Joined

- Aug 23, 2013

- Messages

- 970

Yeah, its over an inch high and to the rear about a quarter of an inch. I think I just wasted a whole bunch of money for something that wont work. Now to find someone who needs it. TimI think that's going to be a lot of work to get it lined up properly, looking at the way it fits (or not) on the ways.

- Joined

- Aug 23, 2013

- Messages

- 970

I made a few purchases this week, I bought a Jacobs flex collet chuck and collet set on ebay, there was a metric transposing gear set and I bought a brand new Taiwanese 5c collet closer. I now have every option that came with an 11" Rockwell lathe. When I get pictures, I will post them. Tim

- Joined

- Oct 7, 2013

- Messages

- 305

I've been looking at collet closers lately. Hurry up with the pics. I want to see what you got!

Tim, did you end up with a BXA or AXA QC toolpost? There is a BXA right now on ebay I have been thinking about bidding on. I have never used one, and I'm afraid the BXA might be a little large for the DR11.

Tim, did you end up with a BXA or AXA QC toolpost? There is a BXA right now on ebay I have been thinking about bidding on. I have never used one, and I'm afraid the BXA might be a little large for the DR11.