- Joined

- Jul 10, 2013

- Messages

- 1,190

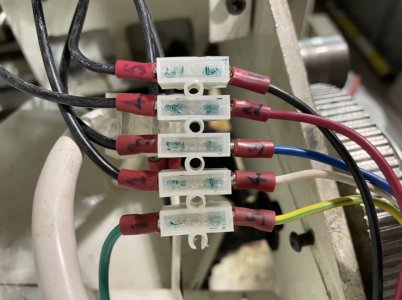

Do you have the 9" Lathemaster? Mine is the 8x14. The on/off switch, the drum, and the wiring is different from mine. Even the wires are white not black although there are other colors. I would recommend not to do the reverse wire short test. The test may tell you what you need to know. The trouble is that there is so much current going through the switches that you may burn the switch contacts. I believe that is why the switch would chatter when you turn the lathe on even after you rectify the main problem. End up replacing both switches because some of the contacts measured over 20 ohms when close. They should measure close to zero. Marba633csi has a good point about the import switches of that type. I replaced mine with a standard drum switch. Modified it so it would fit in the original place. This switch can handle up to a three-horse motor and was much simpler to wire. As for testing the motor. Since you have already opened it up. There should be five wires coming out of the motor. Hopefully, the color code should be the same as mine. Green is ground. U1 and U2 are black and white and are the run winding. V1 and W2/Z2 are the run winding. If you take an ohmmeter to the green and the other lead to any of the four other wires, they should measure open or infinity. If one of the wires measure any kind of short to the green or the metal ground, there is your problem. Most likely, it will be V1 or W2/Z2. You will have to take the motor apart and find the open insulated wire that is causing the short. Good luck, Mark.