- Joined

- Jul 10, 2013

- Messages

- 1,190

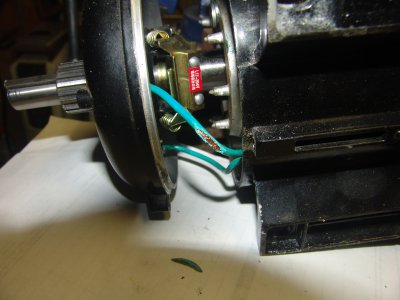

I have a Lathemaster 8x14 about 10 years old. The magnetic on/off switch started chattering, then only start but would not run. Traced the problem to a loose clamped on lug. Replace and still had some chattering when turned on. And just for grins tried to run it in reverse. Blew house breaker. I don't use the reverse much but it did work before. Traced problem to a couple of contacts in the forward/ reverse switch. Both contacts measured about 20 ohms when it should be zero. Not good, Before ordering anything traced the wiring and made a schematic. The guy that wired this thing must be totally color blind and get his kicks out of staring at bowls of cooked ramen. Example. the hot wire on the power cord is black, good. Then it is connected to a GREEN wire, then red, then white. The neutral on the power cord is white, good, then brown (huh). I won't even describe the mag switch and all the circuit loops. By the way the mag switch has no nomenclature of any sort. So started from scratch, Replaced both the mag switch and the forward/reverse switch with common standard mag switch and drum switch and made the wiring simple. Works great, except that it still blows breakers on reverse. The motor has a start and run caps. Can that be the problem and if so why? I know that motor caps are really two caps in one. Could one be shorted? They don't measure that way. Any help would be greatly appreciated. Mark

Went back and read the past comments. Mark, I hope that you are right. Really hate to spring for a new motor. Anyway, thanks for the help guys. I'm done for the night and deal with it tomorrow.

Went back and read the past comments. Mark, I hope that you are right. Really hate to spring for a new motor. Anyway, thanks for the help guys. I'm done for the night and deal with it tomorrow.