I don’t have anything that I’m aware of that I can do anything you recommended. I don’t know anybody with any 3-D printing or laser printing skill sets. There is a local place that will do laser engraving, but I still would need to find the correct diameter steel piece and I’m going to guess I’m going to need to know how much space in between each mark there needs to be. Unless the laser engravers software can figure that out.Aha! That's not in the parts list in my manual. Thank you!

Even a good FFF/FDM 3D printer (the melty plastic kind) won't produce a good result here, speaking as someone who has 3D printed plenty of text including on a reasonably high-precision printer (good enough to print working threads). You might get a good result from an SLA printer (cured resin type), but many of those are too small.

Could print them in reverse on a transparency, and then glue the transparency upside down to metal to protect the markings?

Print them in reverse, but also inverted (mirror image and reversing black and white) on transfer paper and use it as a mask for acid etch?

In my case, I scanned the plate when it was removed, next to a scale, used the scale to validate the dimensions of the 600dpi scan, then used three-point circles on the curves to find a circle.

Then I realized that I could measure the diameter of the circular features of the t-nut track and the offsets to get precise diameter for the curves of the plate. That was gratifyingly close to my first approach with the scanner. While I haven't yet manufactured it, I have reasonable confidence in the result. (If it's a little bit off, it's just tweaking a few constraints in the model.)

I’m all very new to this, just finding material to be a struggle.

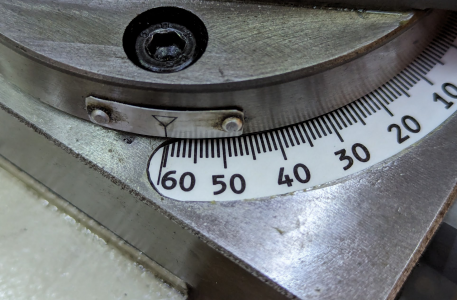

Currently, my compound the degree scale is just a flat tape around the outside, circumference of the compound body. Heck if I can find somebody confident with a laser engraver, I would just have them transfer what is on the tape now onto the actual steel body of the compound