- Joined

- Sep 8, 2019

- Messages

- 4,392

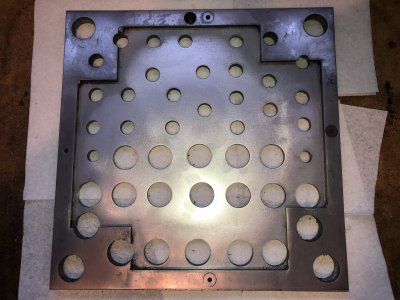

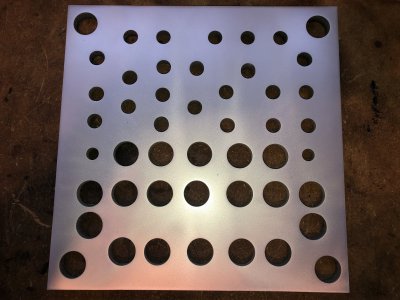

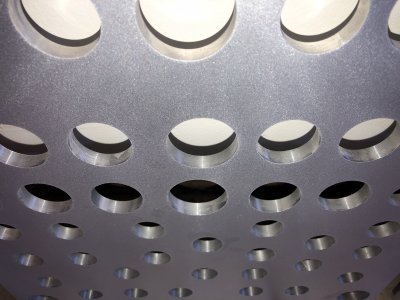

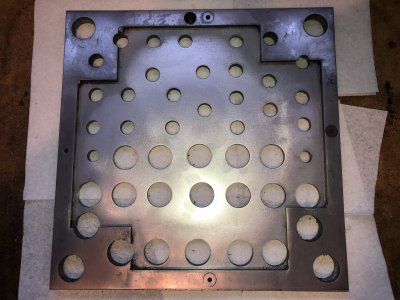

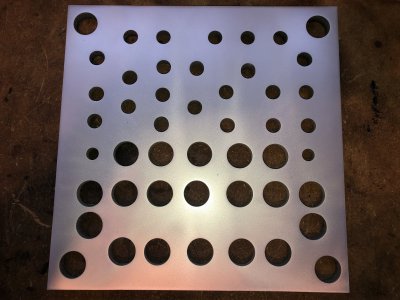

I was too tired from my work week to even touch this project yesterday. Today (Sunday) I drilled the 3/4” and 1-1/4” holes in the last shelf.

I also did a quickie (flap disk) knocking down the high points (which were the high parts of 3 bolt heads) on the back side of the shelf.

Now I am going to make the last 3 posts. These are made from 1-1/4” muffler tubing. So I spent about 5 hours of my day on the knee mill, and my evening will be on the engine lathe.

I also did a quickie (flap disk) knocking down the high points (which were the high parts of 3 bolt heads) on the back side of the shelf.

Now I am going to make the last 3 posts. These are made from 1-1/4” muffler tubing. So I spent about 5 hours of my day on the knee mill, and my evening will be on the engine lathe.