- Joined

- Sep 10, 2022

- Messages

- 929

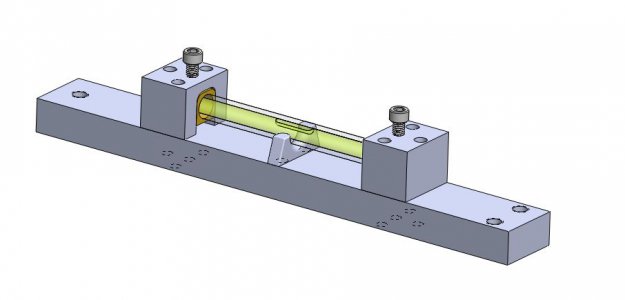

This time of year at work it is a bit slow. So I decided to make a precision level. I will be buying the vile for a Starrett 98 6”. Only $25 on Amazon. In the meantime I had a section of 1”x1-1/2”x about 6-1/2”. Of CRS.

I am just roughing out the base right now. I have the bottom flat and the 1/2” ball slot cut

cu

Next up is cutting the 45 off of the ball cut. Then setup an angle to remove so me excess material from the top.

Cutting oil is my blood.

I am just roughing out the base right now. I have the bottom flat and the 1/2” ball slot cut

cu

Next up is cutting the 45 off of the ball cut. Then setup an angle to remove so me excess material from the top.

Cutting oil is my blood.