- Joined

- Jul 26, 2013

- Messages

- 584

Good morning, Carroll

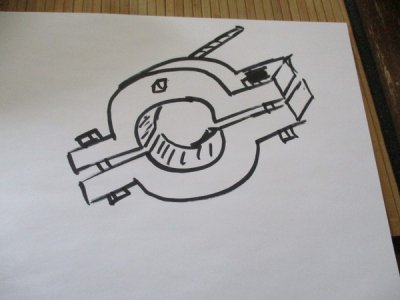

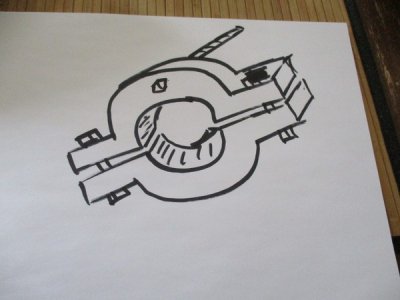

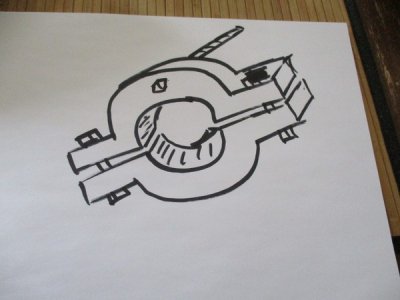

Where you have a wood lathe, I suggest that you make a driving dog out of wood to drive the shaft. Maybe glue two layers of 3/4" plywood together, bore it out close to the OD of the gear, split it down the middle and then contour the outside so that you can run a couple of bolts through each side to act as a clamp onto the gear. The drill for a bolt at right angles to the clamp to act as a driver against one of the chuck jaws.

Here's a crude drawing to show what I mean...

I think this method would be kinder to the teeth on the gear and provide enough drive to do your cutting, as long as you take light cuts.

Brian

Where you have a wood lathe, I suggest that you make a driving dog out of wood to drive the shaft. Maybe glue two layers of 3/4" plywood together, bore it out close to the OD of the gear, split it down the middle and then contour the outside so that you can run a couple of bolts through each side to act as a clamp onto the gear. The drill for a bolt at right angles to the clamp to act as a driver against one of the chuck jaws.

Here's a crude drawing to show what I mean...

I think this method would be kinder to the teeth on the gear and provide enough drive to do your cutting, as long as you take light cuts.

Brian