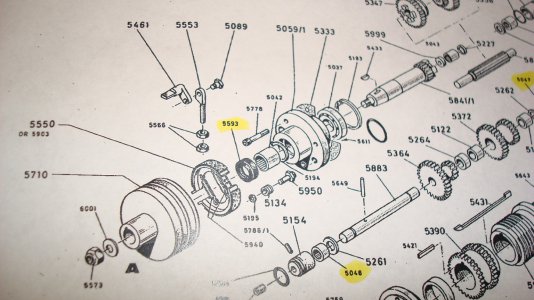

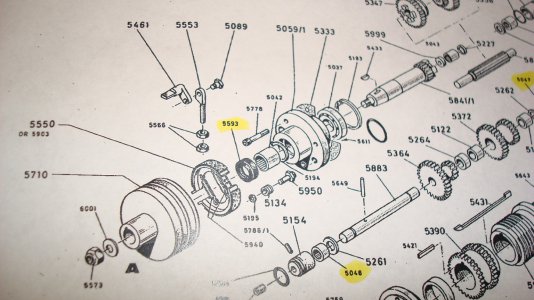

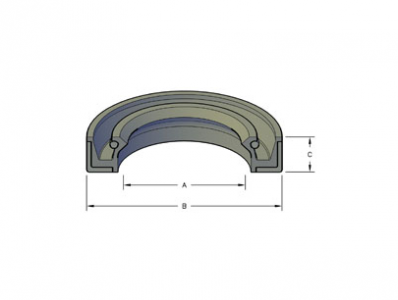

Good afternoon guys,well I have ran into another hurdle today on my 13" 1965 Colchester lathe.I have couple other post in this section where I talk about some of the issues such as the limit switch.Just the other day I over come that problem with the help of some members here.So I move on to my next hurdle which is oil leaking from a sealed bearing but coming from the spindle head.Not know what was behind that bearing I called Clausing with the part #'s from my manual thinking that all I needed was the oil seal since its leaking Right??? Well they don't have those anymore but I ask if they could email me a diagram with specs so that maybe I could find one that would fit.Haven't heard back yet so though I would take this alittle futher.So today I pulled that section which all it took was removing the pulley(which was cover w/oil) then 3 bolts that section just pulled out.Well with my manual in front of me I took apart that section one piece at a time which before I thought it was perfect when I spin the shaft by hand(so smooth)but there is a roller bearing missing and what I thought was the oil seal is what I also thought was just a plain bearing and it was just a plain bearing with Japan on it.So yrs ago someone replace the oil seal since maybe it was not available back then but done away with the roller bearing since they went back with just a plain seal bearing.And I bit it still leak back then.So here some pics of my problem.Hoping maybe someone someplace either here in the states or UK will have an answer for a fix.To me this is earth shaking problem---Help kroll