- Joined

- Sep 23, 2010

- Messages

- 280

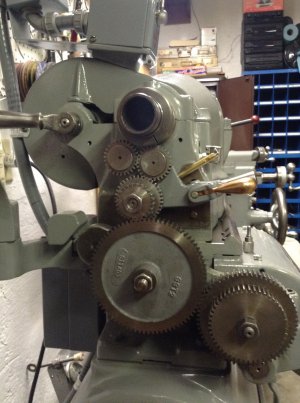

Ok ,I took a couple shots of the side. Let me know if there is anything else I can do for you.Hello,

Can you post some detailed pics of the banjo assembly?I need specifically to see the pinion slide knob and related parts.

I could really use some dimensions on the pinion knob,the tooth count on the slide pinion gear.

I have a "13" and it would help greatly if I knew what was needed to complete the Primary Drive Assembly.

I will post a pic of the Banjo and the missing Slide Gear Assembly(which bolts to the center hole)that is currently empty.

Mine was Manufactured in 1941 but I believe they share the same Headstock Assembly.

Thanks man.

Last edited: