-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

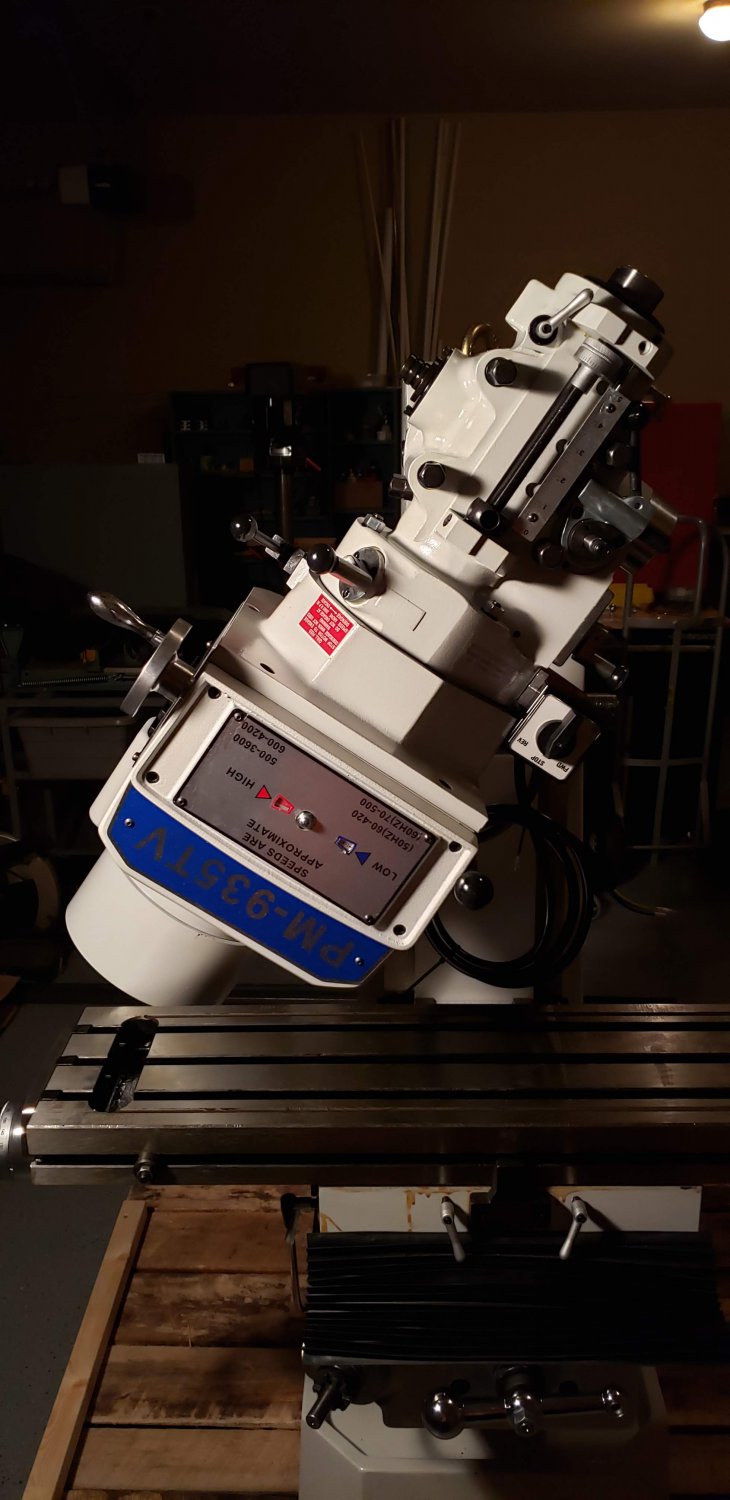

New PM-935T-V Milling Machine has arrived

- Thread starter riveter

- Start date

- Joined

- Jan 26, 2021

- Messages

- 344

I have made some T-Slot covers since that photo was taken. No more newspaper.Now that's more like it! Still cleaner than mine most days...

I want to rotate the mill head to the upright position. The user manual says:

How do I do this without damaging anything? I am working alone, so all I can think of is using a shop crane and strap to support the motor while I loosen the four bolts and crank it into the upright position. Is there a better way?If it is necessary to swivel the head for hoisting purposes, partially loosen the four head mounting bolts, Figure 2-1, while supporting the head to prevent sudden movement. Continue supporting the head while using a wrench on hex head #1, Figure 2-2, to crank the head to the desired position.

There should be 4 bolts holding it in place. There will be a 5th bolt that you turn to move the head.

Although I have a Grizzly I used my left hand to push/steady the head up and the right to ratchet the bolt that moves the head. One direction turns the worm gear up (moving the head), the other moves it down.

Although I have a Grizzly I used my left hand to push/steady the head up and the right to ratchet the bolt that moves the head. One direction turns the worm gear up (moving the head), the other moves it down.

Loosen the 4 bolts on the column and rotate everything 90° to the left so the head is over the side of the mill. Not reaching over the table makes it easier to lift. With the 4 head bolts slacked off you should be able to push up with your left hand while turning the worm to bring the head up. It isn't that bad and can be done in stages to rest if needed. The gear will support the static weight just fine if you need to stop.

- Joined

- Jun 12, 2014

- Messages

- 4,811

I would read the manual. There are 4 long bolts (red) that you slightly loosen on the front of the head, the head is geared so it should not move when front bolts are loosed. There is a bolt head (blue) which is turned in either direction to raise/lower the head. Attach a ratchet socket wrench with a small extension, lift the head with one hand and ratchet with the other, and/or use an electric socket wrench. You will need to tram the head in both X and Y directions, just lightly loosen the appropriate set of securing nuts, tweak the head position and tighten, then recheck tram as it will change. Both the nod (purple and green) and the tilt (red and blue) of the head are geared mechanical drive.

Thanks for that great explanation and illustration. This my first knee mill so I am trying to follow the user manual closely.I would read the manual. There are 4 long bolts (red) that you slightly loosen on the front of the head, the head is geared so it should not move when front bolts are loosed. There is a bolt head (blue) which is turned in either direction to raise/lower the head. Attach a ratchet socket wrench with a small extension, lift the head with one hand and ratchet with the other, and/or use an electric socket wrench. You will need to tram the head in both X and Y directions, just lightly loosen the appropriate set of securing nuts, tweak the head position and tighten, then recheck tram as it will change. Both the nod (purple and green) and the tilt (red and blue) of the head are geared mechanical drive.

View attachment 406968

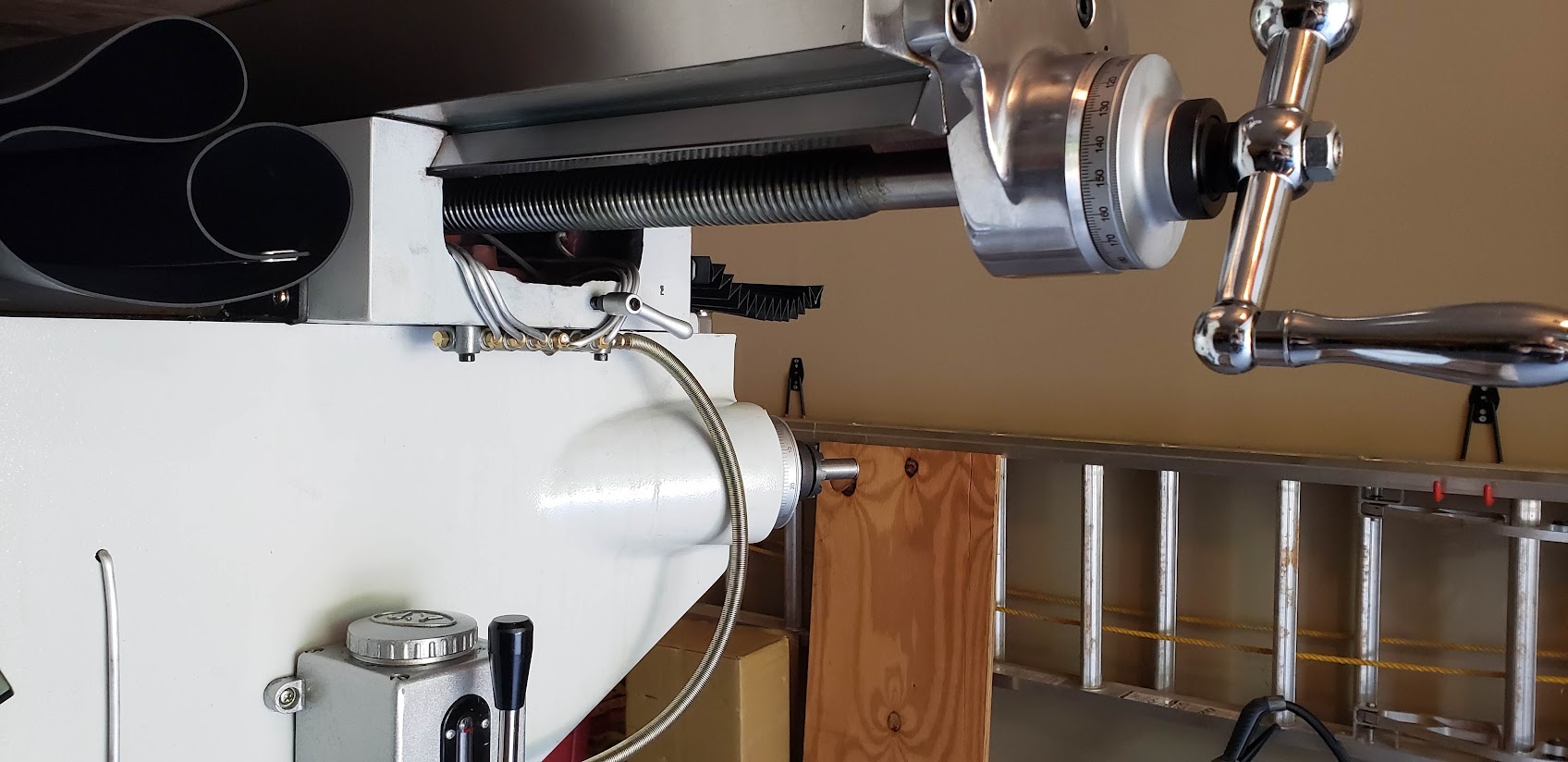

It is not a good day. While inspecting the milling machine table and tramming the head today I noticed a severed oiler line. When I pull the one shot oiler handle, oil shoots out the severed end. It looks like the line was struck from beneath close to the fitting. Whatever happened, it is cut right off. The crate was fully intact, so I don't think it happened in shipping.