Welcome, Dudeman. Looks like you're from my hometown. I haven't been there in 20 years, though. I hear it's changed...

For that type of rust, I like phosphoric acid based rust removers (naval jelly, evaporust, oxpho rust) because they kill rust dead and leave a finish that will hold oil for future protection. Thin woodsman mentioned electrolosys, which you may want to look into. I use 1/3 cup of arm & hammer sodic carbonate (a.k.a. laundry booster) per gallon of warm water as electrolyte and rebar as the anode across an automotive battery charger. This is the method you use when you want rusty junk to come out looking like new parts, ready for paint and assembly.

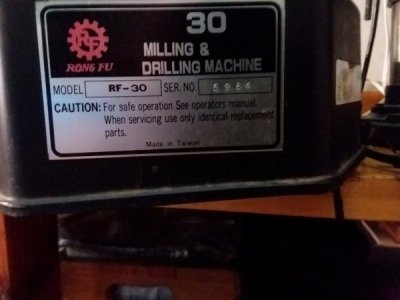

Your mill is one of the older Taiwan-made Rong Fus. Same as what I have. With a little work, some adjustment, and the addition of a power feed and DRO, you'll have a capable machine. A good vise is a must, and proper R8 tool holders should be used, but you've got the bulk already covered by having the machine in hand already. Keep posting as you go!