Yeah, this is the route I will go. I will fit my existing backing plate to the new chuck and then have the old one around for a rotary fixture or whatever, as someone else suggested. Thank you!I’m with ShagDog on this.

Buy an inexpensive (was gonna say cheap, but they are actually well made)import 5” 3 jaw chuck.

Money well spent.

The only downside is you will probably have to machine a new back plate then spend lots of time cleaning all of the cast iron off/out of your new lathe.

Above all, have fun

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My first lathe!! Old South Bend.

- Thread starter ADM

- Start date

Well, got around to getting another chuck and fitting my existing backing plate to it.

Moving on to the tail stock and I have another question, if I may. The tail stock clamp plate that came

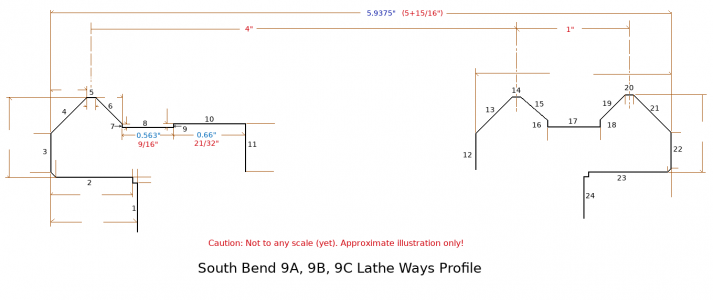

with it sure seems a little narrow. Did they make different sizes? Between the rails on my ways measures right about 2.18" and the clamp plate is not much wider than that. Thoughts?

Moving on to the tail stock and I have another question, if I may. The tail stock clamp plate that came

with it sure seems a little narrow. Did they make different sizes? Between the rails on my ways measures right about 2.18" and the clamp plate is not much wider than that. Thoughts?

Attachments

- Joined

- Mar 21, 2018

- Messages

- 1,600

Moving on to the tail stock and I have another question, if I may. The tail stock clamp plate that came

with it sure seems a little narrow. Did they make different sizes? Between the rails on my ways measures right about 2.18" and the clamp plate is not much wider than that. Thoughts?

Don't worry. The prismatic ways center the tail stock, not the clamp. The clamp only provides a platform for downward pressure.

Your clamp does look a little sloppy. However, the 56N3 is the proper part for a 9" lathe.

- Joined

- Mar 3, 2020

- Messages

- 506

ADM, this is the tailstock clamp from my ‘38 SB9 workshop. Fits great, I always thought it was standard, but maybe not.

My lathe is a “C”, but produced a couple yrs before SB started the A,B & C designations.

I think (?) judging from the top spindle git oilers, yours is from the same time period.

I think our lathes are the earlier “modern” models, as SB was phasing out the 9” junior (or heavy9) at this time period.

I could (of course) be wrong about all of this.

But I don’t think so.

Cheers, Harvey

My lathe is a “C”, but produced a couple yrs before SB started the A,B & C designations.

I think (?) judging from the top spindle git oilers, yours is from the same time period.

I think our lathes are the earlier “modern” models, as SB was phasing out the 9” junior (or heavy9) at this time period.

I could (of course) be wrong about all of this.

But I don’t think so.

Cheers, Harvey

Attachments

- Joined

- Sep 28, 2013

- Messages

- 4,318

mine's a heavy 9, so 2.75" gap between ways, but the difference between the gap and the width of the raised center piece of the clamp is only 1/16", so you may have a clamp from a different lathe or model. I wouldn't worry about it unless it causes issues, like tailstock slipping or the clamp twisting as you move the tail stock.