- Joined

- Apr 28, 2014

- Messages

- 3,590

Perfect. That was my first thought.Power Hacksaw — Keller model 3WA to be exact. My friends have shall we say “ refined “ senses of humour sometimes...

-f

I want one of those styles someday.

Perfect. That was my first thought.Power Hacksaw — Keller model 3WA to be exact. My friends have shall we say “ refined “ senses of humour sometimes...

-f

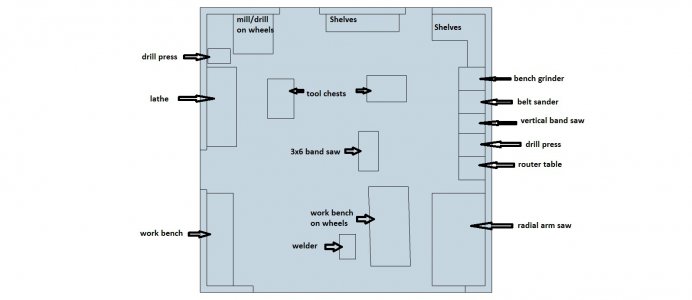

Here is the layout of my garage/shop. It is 21' wide by 21'6" deep. Everything is on wheels except for the lathe, radial arm saw and the work bench against the wall. My 66 MG Midget takes up the open space in the front left side. Right now the Midget is on jack stands while I redo the front suspension. Otherwise it is also on its wheels so it can be moved around. Metal work is done up by the lathe and mill/drill while wood work is done by the radial arm saw or outside on the driveway. This seems to be enough separation to keep the saw dust out of the lathe. I do most of my welding outside as well.

View attachment 315085

Ha. I didn't see (or hear) that one coming!Power Hacksaw — Keller model 3WA to be exact. My friends have shall we say “ refined “ senses of humour sometimes...

-f

I've never sold any tools either. Given duplicates away when my dad gave me a better one, but never sold. I buy tools because I need them for a job I'm going to do. So unless it's something I plan to never do again why get rid of it? I think Mickri and I are in the same situation where few things are static and almost everything is on castors. It's the benefit of having smaller machines. We both went to finding 3 drawer small filing cabinets(two upper letter drawers, bottom file drawer) for little or nothing. I've got one under my Deckel clone and the other two are still on a cart waiting to be incorporated. I was thinking one for my mig/plasma cutter and one under my Atlas shaper. Those three drawers are so perfect for each machine. Like file drawer is perfect for my welding helmet and the letter drawers for consumables and welding tools. I do little wood but lots of other dust making like grinding, powdercoating etc so all my machines are covered so I don't have to worry. My SO loves seeing the stuff I make out in the shop and loves making custom "cozies" for all my machines. The last two were for the mill table and shaper and were made out of the old faded canvas couch covers that she decided to retire. She kept it just for covering the machines, bless her heart and all her vital organsby the way Bi11 Hudson, I too am like you. I don’t think I’ve sold a single tool in my life. Always think, maybe I’ll need it one day.

I've never sold any tools either. Given duplicates away when my dad gave me a better one, but never sold. I buy tools because I need them for a job I'm going to do. So unless it's something I plan to never do again why get rid of it? I think Mickri and I are in the same situation where few things are static and almost everything is on castors. It's the benefit of having smaller machines. We both went to finding 3 drawer small filing cabinets(two upper letter drawers, bottom file drawer) for little or nothing. I've got one under my Deckel clone and the other two are still on a cart waiting to be incorporated. I was thinking one for my mig/plasma cutter and one under my Atlas shaper. Those three drawers are so perfect for each machine. Like file drawer is perfect for my welding helmet and the letter drawers for consumables and welding tools. I do little wood but lots of other dust making like grinding, powdercoating etc so all my machines are covered so I don't have to worry. My SO loves seeing the stuff I make out in the shop and loves making custom "cozies" for all my machines. The last two were for the mill table and shaper and were made out of the old faded canvas couch covers that my she decided to retire. She kept it just for covering the machines, bless her heart and all her vital organs