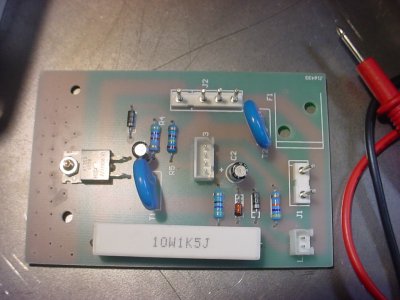

Here's a picture of the board:

View attachment 435096

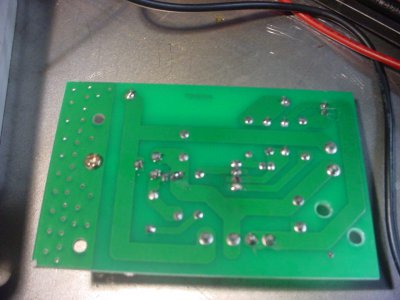

Here's the back:

View attachment 435097

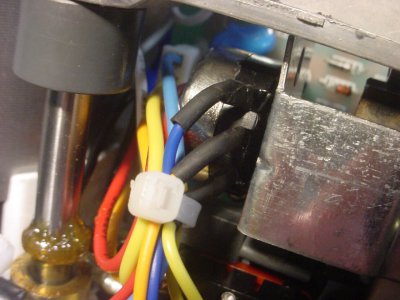

Here's a close-up of the pot connections. They are all shrink-tubed. Would I need to pull off the shrink tube and disconnect everything? Is that even a good idea? I can re-shrink-tube them if I do.

What am I measuring? Do I put a multimeter lead on one terminal and the other on the other ones in turn to see what the resistance is? The leads don't fit in the connectors, by the way; too big.

View attachment 435098

I turned it on and it stayed on this time. I wiggled wires, pulled, moved, etc. and couldn't get it to turn off. I had to pull the power wires to the motor to get it to stop and those do not come off really easy. The wires are really crammed in there; maybe something comes loose?

There is no insulator plate between the circuit board and the outer casing, either. What would I use for this? Anything special?

Also, the circuit board was sort of press-fit into a slot in the outer casing; is this some sort of cheap way to do a heat sink?