- Joined

- Jan 6, 2017

- Messages

- 1,214

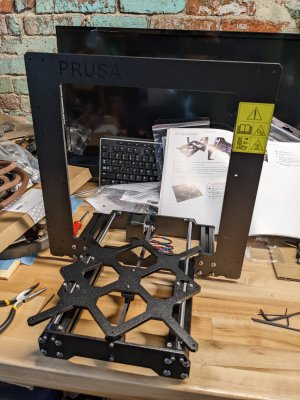

Got up to step 21 in the Y axis tonight. Putting in the 3 bearings was a fiddly operation, seemed I needed one more hand to do the job! Got a bit tired so stopped for the night. Kit seems well made. There's a lot of labor involved, but it's been a good break from my broken x axis DRO on my mill.

Great. I'm eager to see the finished product!