…It was originally 2 phase ...

Also in post #33 I have a video on YouTube which shows you exactly why I need a … to replace the contactor. …The original spindle motor is long gone and someone had replaced it with a single phase 220v and just had a plug to it. … The original Fairbanks Morris shaper motor is on the rear of the overarm and it is a 3 phase motor. The table feed is a Baldor 3 phase industrial motor which doesn't believe to be original either .

I have retrofitted a 1hp 3 phase Bridgeport pancake motor for the spindle …

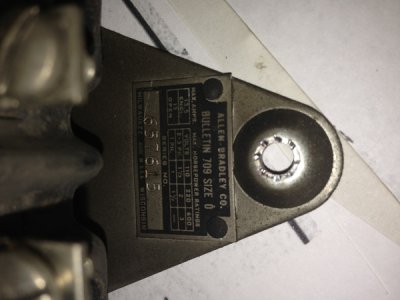

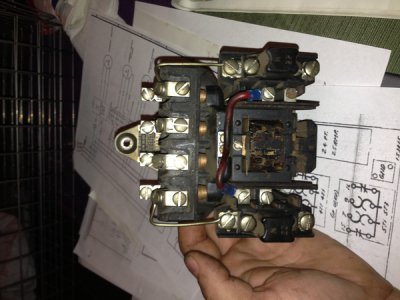

… I will try to find an old AB on eBay or something that is a 3 pole and then I will try my best to rewire using Mikes schematic . He gave me a schematic he made of his working mill and it is 3 phase and he has 4 different motors like me with a slight difference on the toggles .considering I will be hard wiring the machine into the panel with a breaker I don't see the need for the circuit interrupter which is missing the key anyways . So I say I can wore directly from the 3 phase panel into the Contactor/starter and then make sure everything is wired up for 3 phase . Does this sound like the best route?

Josh

…

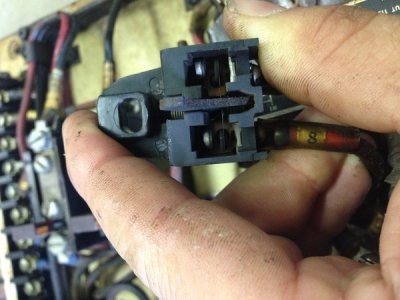

OK, so to summarize, the machine was originally 2-phase and has been extensively modified, probably including all new motors. There’s no way to know if the shaper is original to the machine, but that’s doubtful since you say that it’s 3-phase; I would expect an original shaper to be 2-phase as well. The control panel was wired for 2-phase but appears to be the same physical panel used for 3-phase machines. You now have 3-phase spindle, feed and shaper motors. The original contactor has a bad coil.

Note to the unfamiliar: 2-phase power is not to be confused with single-phase. It was in use in the Niagara Falls area in the first half of the 1900’s.

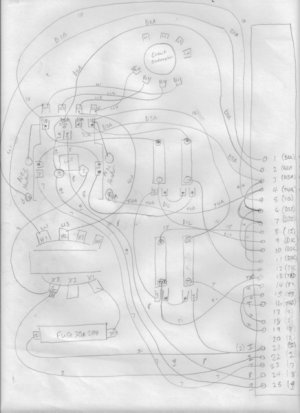

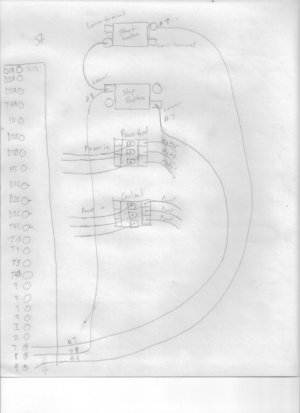

Given the above, I would pull all of the old wiring out of the panel and start fresh using the 3-phase wiring diagram from post #10:

panel wiring

starting circuit

I think that you’ll find that regardless of the start/stop and aux control panel switches, the control panel wiring will be pretty much as shown in the panel wiring diagram. I haven’t seen Mike’s schematic, so I can’t comment on it. But there’s a reason for everything on that panel and you are better off going with a factory wiring design than something else. You don’t know who bypassed what to get Mike’s machine working.

The starting circuit that you posted shows more circuitry above the starting circuit. Can you post the rest of it or e-mail a scan to me? (I'll send you an e-mail.)

The good news on your panel is: a) it’s the same basic panel used for 3-phase machines; b) your transformer has a 120 secondary; c) the panel was originally 220 Volts, so the heaters for all of the overloads are probably correctly sized (or were for the original motors); d) the heaters from the old contactor are the same series used by the replacement contactor that you bought. We’ll have to look at the rating plates for each motor and verify that the overload heaters for all of the overload devices are correctly sized for the new motors

If I understand correctly, the “circuit interrupter” is a safety switch of some type that cuts power to the panel when the door is opened. Is that the case?

I’m very familiar with the Allen-Bradley bulletin 709, size 0 contactor that you bought. It’s rated for up to 3HP on 220/240, so you don’t need a larger contactor. I see that the seller had 5 or so for sale; hopefully, the one you get also has a 120VAC coil, which is what you need. We’ll need to verify that the N22 heaters from the old panel are correct for the replacement spindle motor.

If the machine came with a fused disconnect panel, I would use it rather than wire directly to the breaker panel. Virtually any machine shop you go into you will find fused disconnects on every machine.

One issue that you will need to attend to is to make sure that the two phases used for the starting circuit are the real phases; you don’t want to use the artificial phase from the rotary phase converter in the starting circuit.

Cal