I went out to the shop this morning to work on the engine some more when I realized I didn't have any materials for the intake or the exhaust systems. The parts are on order now.

One of the reasons I wanted to make a 4 cylinder engine was I wanted to use a distributor. I made a prototype to test my ideas and was going to start on a model when I found this for a very reasonable price I couldn't pass up.

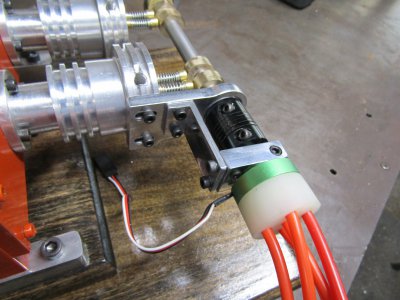

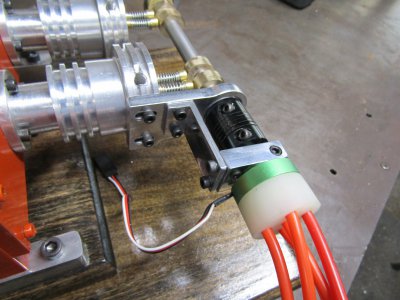

It is a self contained unit of 4 magnets, a hall sensor, a rotor, and a dist cap. All you need is an ignition module, some spark plugs and some batteries to make it complete. It took a month to get here from China but when it did I just couldn't put it aside for later I had to test it.

It works great but the spark plug wires are too short for my engine. I did find some 10,000 volt ignition wire of the same size that will be here next week and then I can replace the short wires.

The dist is mounted on the left bank's cam shaft using a flexible coupling and a rigid bracket attached to the cam bracket. That way when adjusting the cam bracket everything will stay in alignment. The ignition timing is adjustable by loosening the clamp screw and turning the dist.

If this works out it will be a very neat , easy and compact ignition system.

Thanks for looking

Ray