-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just Ordered a PM1127-VF LB!!

- Thread starter lpeedin

- Start date

Overall impression of the lathe is that it is a good piece of equipment at a size and price point that nobody else is competing with. It is long enough and has a large enough bore to do a lot of things that a 12 x 36 lathe can do. The fit and finish of my machine was really good. (I have already put a few dents and scratches in things from working with it, mostly due to the stupid spring loaded 3-jaw chuck) I did play with the settings on the speed control board to get things where it runs really well and there is no noticeable "bogging down" when doing a heavy cut or when threading. My only real complaint is that the drive pulley for the motor and the drive pulley for the spindle are slightly out of round. They do not appear to have been made on a lathe, but rather possibly forged and then just the hub was reamed and broached for a keyway. If I had access to another lathe, I would simply skim the outside diameter of the pulleys to true it up. This has led to a sort of pulsing sound when it is making a cut. The quality of the cut is not affected in any way, but I hear it when using the machine.

My headstock alignment appears to be very good. I have about .0005" diameter taper over approx 6" without using the tail stock. I checked this by making very light cuts on a 2" diameter aluminum rod.

The tailstock is actually MT3, not MT2. The qctp is AXA sized. You are correct, one can never have too many tool holders! Plus it comes with a 6" 4 jaw chuck, two MT3 dead centers, a MT3 live center, and a MT5 - MT3 adapter. Then there is the steady rest, and a follow rest.

With all of that said, I am very happy with my purchase. Every machine is going to have some quirks. I did make new knobs to replace all of the cheap plastic knobs that came on the machine. Many of them are the same knobs that are on my little X2 mini milling machine.

Good thing you understand your quoted delivery time is most likely not the case. Mine hit delays at the shipping docks due to a strike by the dock employees. Matt is great to work with. I know this for sure because he responded to each and every one of my emails or inquiries. In fact, since I had my lathe delivered, he has sent me (3) different follow up emails making sure I am happy and checking to see if I had any issues. Some of those were as late as midnight!

You will be happy. It will be worth the wait.

My headstock alignment appears to be very good. I have about .0005" diameter taper over approx 6" without using the tail stock. I checked this by making very light cuts on a 2" diameter aluminum rod.

The tailstock is actually MT3, not MT2. The qctp is AXA sized. You are correct, one can never have too many tool holders! Plus it comes with a 6" 4 jaw chuck, two MT3 dead centers, a MT3 live center, and a MT5 - MT3 adapter. Then there is the steady rest, and a follow rest.

With all of that said, I am very happy with my purchase. Every machine is going to have some quirks. I did make new knobs to replace all of the cheap plastic knobs that came on the machine. Many of them are the same knobs that are on my little X2 mini milling machine.

Good thing you understand your quoted delivery time is most likely not the case. Mine hit delays at the shipping docks due to a strike by the dock employees. Matt is great to work with. I know this for sure because he responded to each and every one of my emails or inquiries. In fact, since I had my lathe delivered, he has sent me (3) different follow up emails making sure I am happy and checking to see if I had any issues. Some of those were as late as midnight!

You will be happy. It will be worth the wait.

- Joined

- Feb 24, 2015

- Messages

- 1,382

It is great to hear you are mostly happy with your new lathe. Too bad about the belt pulleys. Perhaps there is a pulley fabricating adventure in your future?

I guess a MT3 is better. :-\ Fortunately, 1127 is suppose to include a tailstock chuck.

I guess I'll just have to get a a sleeve adapter for MT2 to MT3. I have a nifty MT2 live center with changeable centers of varying diameters I'd love to be able to keep using.

I think I have devised a plan for a stand. I have a large heavy duty HF tool chest, rated for 3000 pounds. It is 44" x 18". I can make a sturdy top that over-hangs the ends enough to support the lathe. I've designed a steel trolly base to replace the wheels consisting of two 4" stationary steel wheels on an axle outboard of the end, and adjustable outboard feet for the other end. The rig will lower the height of the box about 4" lower than the standard wheels, increasing stability.

I'll make a socket and custom mule to move and steer it. I'm toying with the idea of making the mule steerable to increase stability when making sharp turns. My worry is that 18" is not enough width. If I decide it isn't, I can extend the width of the trolly a few more inches for stability.

I guess a MT3 is better. :-\ Fortunately, 1127 is suppose to include a tailstock chuck.

I guess I'll just have to get a a sleeve adapter for MT2 to MT3. I have a nifty MT2 live center with changeable centers of varying diameters I'd love to be able to keep using.

I think I have devised a plan for a stand. I have a large heavy duty HF tool chest, rated for 3000 pounds. It is 44" x 18". I can make a sturdy top that over-hangs the ends enough to support the lathe. I've designed a steel trolly base to replace the wheels consisting of two 4" stationary steel wheels on an axle outboard of the end, and adjustable outboard feet for the other end. The rig will lower the height of the box about 4" lower than the standard wheels, increasing stability.

I'll make a socket and custom mule to move and steer it. I'm toying with the idea of making the mule steerable to increase stability when making sharp turns. My worry is that 18" is not enough width. If I decide it isn't, I can extend the width of the trolly a few more inches for stability.

I think you will be iffy with your stand idea. When you put 600# 44" off the ground, it can get a little top heavy on a base only 18" wide. The chip pan itself is approx. 17" wide x 49" long. I can't remember the actual footprint of the base of the lathe, but it is a couple inches less than the chip pan length. Your chip pan will hang over on the ends, but I think the actual foot print of the base feet will easily fit on top of your proposed stand width.

- Joined

- Feb 24, 2015

- Messages

- 1,382

I think you will be iffy with your stand idea. When you put 600# 44" off the ground, it can get a little top heavy on a base only 18" wide. The chip pan itself is approx. 17" wide x 49" long. I can't remember the actual footprint of the base of the lathe, but it is a couple inches less than the chip pan length. Your chip pan will hang over on the ends, but I think the actual foot print of the base feet will easily fit on top of your proposed stand width.

Thanks for the comments, 3dshooter.

44" was a typo and was referring to the width of the case. I should have typed 42".

The xyz case dimensions are 42" x 18" x 33". With 6" casters the top is currently 39" from the floor. With the trolly I'll make, the top will be about 35" from the floor counting the additional .75 top thickness and 1" clearance from the floor and will have much more lateral stability than the current casters.

I can ameliorate top heaviness some by storing heavier items like extra chucks and rotary tables in the bottom drawers, which is what I do with my current set-up with my G-4000.

I did a drawing in Adobe Illustrator based on the dimension drawing on the PDF manual I downloaded which just shows the over-all dimensions, and scaled it up to match the dimensions so I could extrapolate some fundamental measurements.

The foot print of the lathe itself is well under the 18" depth of the cabinet. The trick will be getting the meat of the lathe centered on the 18" box depth. I may have to modify the chip pan some by relocating the mounting holes, as I'd prefer it didn't over-hang the top drawer of the case. I don't mind the cranks over-hanging the front.

GaWajn, I can say that it was worth the wait. I am a pretty impatient person when it comes to receiving something I ordered, and Matt put up with me well!! If you are looking for a great 110 volt machine, this is the one for you!

- Joined

- Feb 24, 2015

- Messages

- 1,382

I gave Quality Machine Tools a call yesterday to check the progress on my ordered PM1127. They are expecting it in a couple weeks, then another couple weeks for them to set it up and ship it to me.

3dshooter most generously made some measurements for me to assist in my stand design which confirmed that the tool chest I plan to use will be sufficient. I'm in the process of working out the details of the mobile base for the tool chest. It will have two 3-inch iron stationary wheels outside the left end mounted on a center pivot with adjustment screws. This arrangement will allow the box to be closer to the floor.

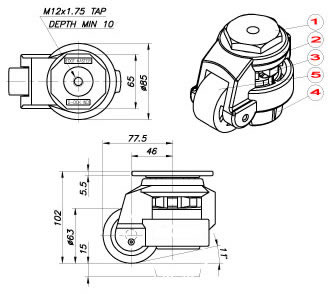

The other end will rest on height adjusting bolt-mounted swivel casters, rated at 1100 pounds each I ordered online yesterday. They will mount to brackets also outside the end of the box. Floor clearance will be one inch.

My experience trying to maneuver very heavy equipment on 4 swiveling casters has not been good, thus I'm using two stationary wheels and two swivels for steering.

3dshooter most generously made some measurements for me to assist in my stand design which confirmed that the tool chest I plan to use will be sufficient. I'm in the process of working out the details of the mobile base for the tool chest. It will have two 3-inch iron stationary wheels outside the left end mounted on a center pivot with adjustment screws. This arrangement will allow the box to be closer to the floor.

The other end will rest on height adjusting bolt-mounted swivel casters, rated at 1100 pounds each I ordered online yesterday. They will mount to brackets also outside the end of the box. Floor clearance will be one inch.

My experience trying to maneuver very heavy equipment on 4 swiveling casters has not been good, thus I'm using two stationary wheels and two swivels for steering.

I gave Quality Machine Tools a call yesterday to check the progress on my ordered PM1127. They are expecting it in a couple weeks, then another couple weeks for them to set it up and ship it to me.

3dshooter most generously made some measurements for me to assist in my stand design which confirmed that the tool chest I plan to use will be sufficient. I'm in the process of working out the details of the mobile base for the tool chest. It will have two 3-inch iron stationary wheels outside the left end mounted on a center pivot with adjustment screws. This arrangement will allow the box to be closer to the floor.

The other end will rest on height adjusting bolt-mounted swivel casters, rated at 1100 pounds each I ordered online yesterday. They will mount to brackets also outside the end of the box. Floor clearance will be one inch.

My experience trying to maneuver very heavy equipment on 4 swiveling casters has not been good, thus I'm using two stationary wheels and two swivels for steering.

View attachment 99595 View attachment 99596

Those are interesting castors... I was gonna use them... yet when I upgraded from a PM932 to a PM935... figured the weight of the machine would be an issue.

I have 6 of them... may put them up for sale at the appropriate thread here at HM forum.