- Joined

- Feb 5, 2014

- Messages

- 198

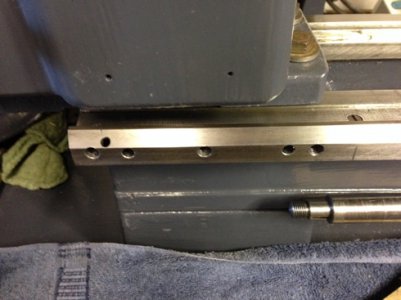

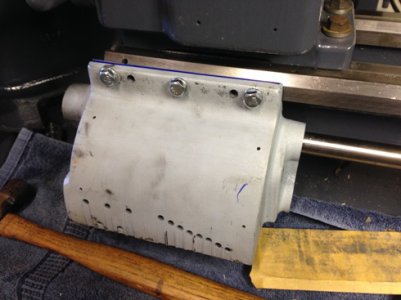

Last night i tackled the gear box mount surface. What a pain to align.

My guide was this web site.

http://madmodder.net/index.php?topic=7917.0

After borrowing some adjustable stands and finding suitable clamps i began to align. About an hour later i had the average readings all under .001". I say average as the surfaces themselves were not very flat to begin with. I took this as assurance that i did not have to hit the alignment dead on.

I noticed a calculation error in one of my previous posts. I added 1" to one of my measurements. So the .920" material removal should have been .08". Good thing i found that before i cut.

I overcut both surfaces a little so i did not have to re-align on the mill and instead plan to shim on the lathe. A test fit after milling show that i am about .010" off in both directions which is what i wanted. Will start shimming out and then mark and drill the holes.

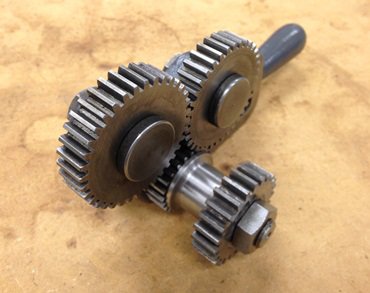

I also finished the new key for the new stud shaft. Hope to have the shaft done tomorrow.

My guide was this web site.

http://madmodder.net/index.php?topic=7917.0

After borrowing some adjustable stands and finding suitable clamps i began to align. About an hour later i had the average readings all under .001". I say average as the surfaces themselves were not very flat to begin with. I took this as assurance that i did not have to hit the alignment dead on.

I noticed a calculation error in one of my previous posts. I added 1" to one of my measurements. So the .920" material removal should have been .08". Good thing i found that before i cut.

I overcut both surfaces a little so i did not have to re-align on the mill and instead plan to shim on the lathe. A test fit after milling show that i am about .010" off in both directions which is what i wanted. Will start shimming out and then mark and drill the holes.

I also finished the new key for the new stud shaft. Hope to have the shaft done tomorrow.