Final Gear Box Alignment

Now that i know the length of the Stud Gear shaft i can locate the gear box along the bed. I expect it to overhang the left edge of the bed and the left most mount hole to be near the end of the bed.

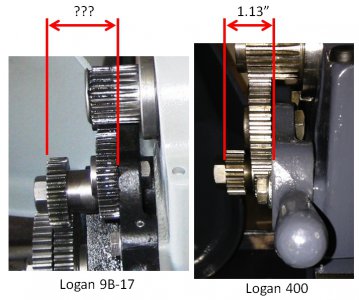

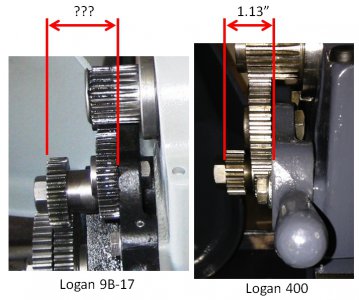

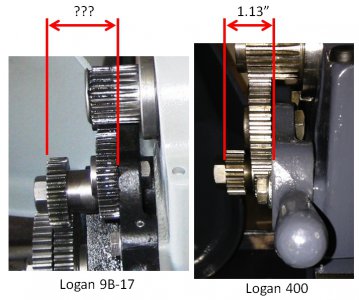

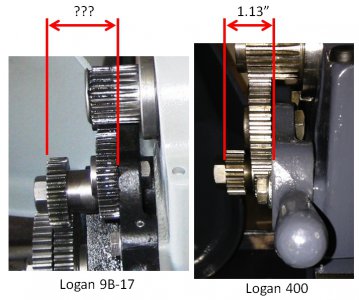

Setting the gear that the Stud gear interfaces with to 1.66" sets the gear box ~ .410" overhung from the end of the bed. Right where i thought it would be. These holes are now marked for drilling later. I will not drill them until i get the lead screw aligned properly.

Lead Screw Alignment to gear box.

In previous posts i have shown that the lead screw does not align to the box. The power apron from the 9B (as reported on the larger Logans) changes that location. I will have to mill the box down but by how much?

I decided to try a new approach. The half nut engages the lead screw but allows some radial play. What if i grabbed the lead screw on the area that is not threaded. That would center the shaft really well on the closing center of the half nut. Assuming the OD of the lead screw is concentric with the thread center (which i think is fair) i could grab that part of the shaft to show where the gear box needs to be. The other bonus is that i will be grabbing the shaft near the end which minimizes the overhang of the shaft. Also i have the tail end of the shaft in its mount which i have already shown to be OK.

Does this all sound fair to you guys?

The center of the Lead screw from the bottom of the bed is 2.77"

The center of the lead screw to the face of the bed is .35"

Note that both measurements are to the mount surfaces for the box.

Now where is the input shaft location on the box?

The center of the Lead screw input bore from the top of the gear box is 1.85"

The center of the Lead screw input bore from the mount face of the gear box is .30"

That means i should have to remove from the mount surface of the gear box:

2.77" - 1.85" = .92" from the top.

.35 - .30 = .05 from the face.

I will baby step into this one. Fortunately you can always shim back out.

The change gear cover does not fit??

Rex or any other 9B owner. Can you take a few pictures of your cover as it closes down on the gear box? Mine does not close so i am betting the red below is removed from the 9B.

I have these from an unknown owner and it looks like it is cut back. I also see the hole in there. Is that the grease the shaft just below the stud gear? I have the change gear chart there. Hm....

What is next?

- Making a new stud gear shaft.

- Making a new gear selector shaft.

- Modify (shorten) the Rack.

- Make riser blocks.

- Drill & tap bed for box mounts.

- Mill box to align shaft.

- Rebuild gear box

- Mount it all

- Re-make the ID plate.

I see things to do for at least another month.