- Joined

- Feb 5, 2014

- Messages

- 198

I think i mentioned this already but i am catching up still on info for this part of the project. I am farther along then what is show and am going back to document progress.

Next step is to take it all apart. Goal is to clean and re-paint but also get to the casting all by itself so i can start fitting it to the bed without the extra 10 pounds of metal.

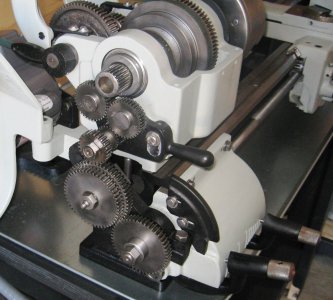

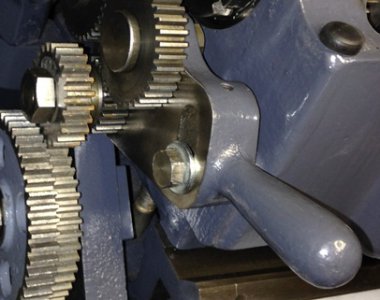

It came apart fairly easy. The Selector knobs shaft did not want to come out of the selector body and getting the pin in the selector shaft (between the two selectors that keeps them separate) was a challenge but otherwise this was straight forward. Since all the gears for the cluster are notched for a key it is easy to ID them while the gears for the selector have a the key integral to the gear. Also all of the double gears are the same part #. The Logan we site also has a cut-away of this to aid in re-assembly.

http://www.lathe.com/gearbox.htm

Wear wise the gears are in great shape. The selector shaft has play in the bushings as does the cluster shaft. Anyone have any idea how much radial slop is allowable?

Here is that casting number. LA-1201. Again this is from the 9B-17 with Power cross feed.

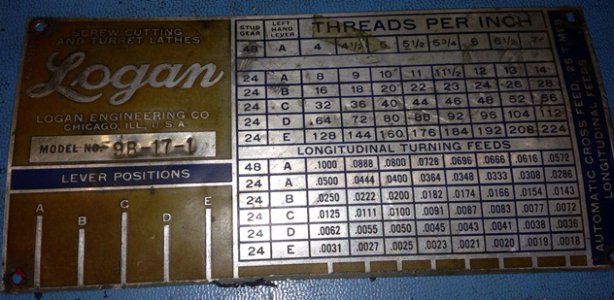

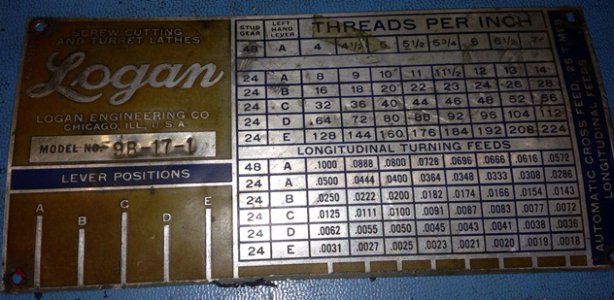

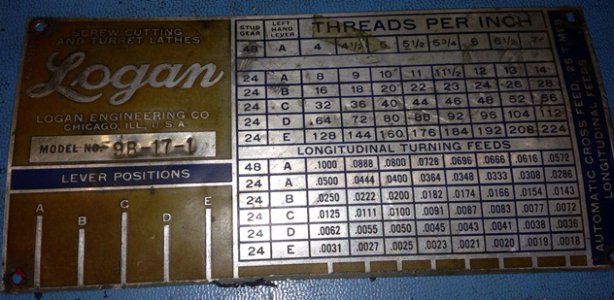

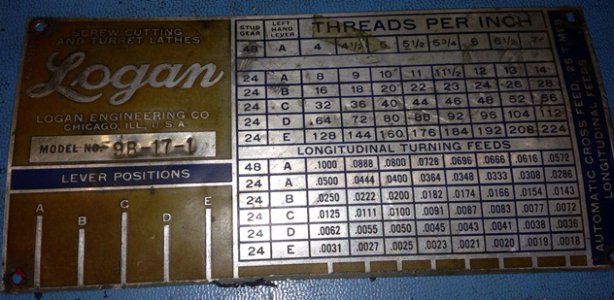

This is the ID plate. Hard to tell from the picture but the red paint is faded and the upper right has been damaged. It would not be possible to flatten it out, paint it and then sand off the top to bring the aluminum back and reveal the details. (Like i did for the Logan 400 ID plates) The other bummer is that Logan does not sell this ID plate. They sell this one.

http://store.lathe.com/lp1785b.html

It is for the newer boxes and uses a different stud gear. That is OK. I have a plan in the works to make my own ID plate. Will work on that later.

Matthew

Next step is to take it all apart. Goal is to clean and re-paint but also get to the casting all by itself so i can start fitting it to the bed without the extra 10 pounds of metal.

It came apart fairly easy. The Selector knobs shaft did not want to come out of the selector body and getting the pin in the selector shaft (between the two selectors that keeps them separate) was a challenge but otherwise this was straight forward. Since all the gears for the cluster are notched for a key it is easy to ID them while the gears for the selector have a the key integral to the gear. Also all of the double gears are the same part #. The Logan we site also has a cut-away of this to aid in re-assembly.

http://www.lathe.com/gearbox.htm

Wear wise the gears are in great shape. The selector shaft has play in the bushings as does the cluster shaft. Anyone have any idea how much radial slop is allowable?

Here is that casting number. LA-1201. Again this is from the 9B-17 with Power cross feed.

This is the ID plate. Hard to tell from the picture but the red paint is faded and the upper right has been damaged. It would not be possible to flatten it out, paint it and then sand off the top to bring the aluminum back and reveal the details. (Like i did for the Logan 400 ID plates) The other bummer is that Logan does not sell this ID plate. They sell this one.

http://store.lathe.com/lp1785b.html

It is for the newer boxes and uses a different stud gear. That is OK. I have a plan in the works to make my own ID plate. Will work on that later.

Matthew