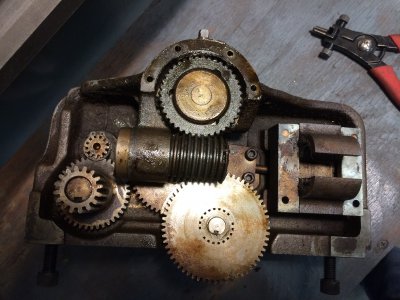

OK, let me try this again while we are looking at the back of my apron:

Upside down, sorry. I corrected it, but it reverts when I upload

Dead center is the worm drive. The internal key picks up rotation from the lead screw which passes though it. It also passes through the half-nuts, but they remain open.

This spins the gear at the top of this photo. It freewheels unless you engage the clutch. Then it drives a gear behind the worm which in turn drives the BIG gear in the lower part of this photo.

That gear is on a lever attached to the selector lever on the front. It swings down (toward the clutch) to pick up a gear that drives the shaft at the left side of this photo, which turns against the rack for longitudinal feed.

Move the lever up and the gear moves up. In the above photo it is in the crossfeed position. You can see it sticks up above the top edge of the apron.

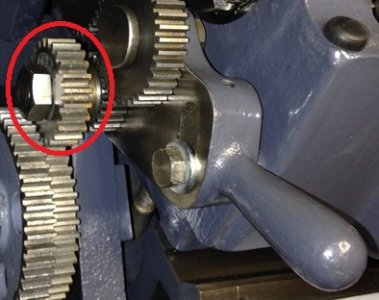

That big gear, when moved up via the feed lever, engages the gear on the crossfeed shaft, as seen in this photo of the carriage:

Hope that helps