- Joined

- Aug 8, 2014

- Messages

- 12

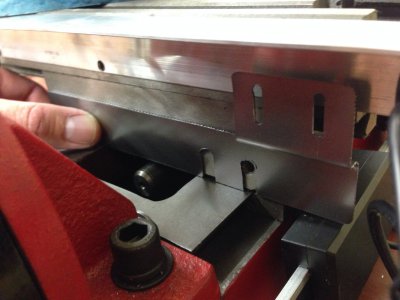

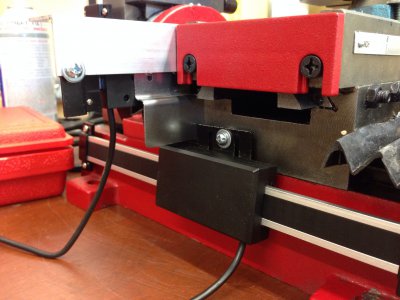

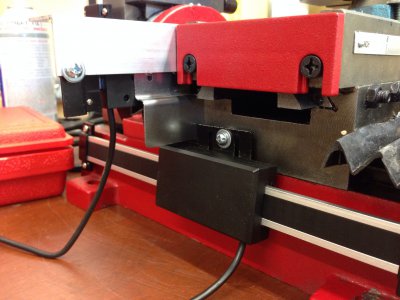

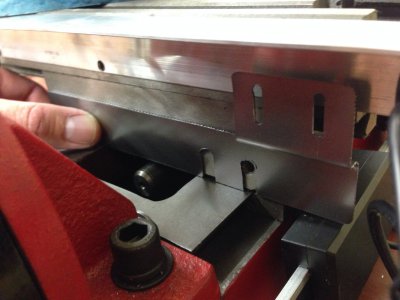

I have my y&z units installed and working nicely, btw. Just trying to determine optimal arrangement for the x.

I see several installs that place the x reader in the center of the table, nobody has crushed theirs against the center column?

Is there any reason these scales couldn't be mounted to the mill without drilling? I've got any number of serious adhesives that would be up to the task, and the benefit then is no holes drilled and I could remove them with a bit of carefully applied heat.

Loctite Speedbonder 324 comes to mind... I'd just need to make certain I have index points set up to keep the mounts from moving.

...or am I overthinking this? That would be like me. A lot.