- Joined

- Dec 22, 2012

- Messages

- 328

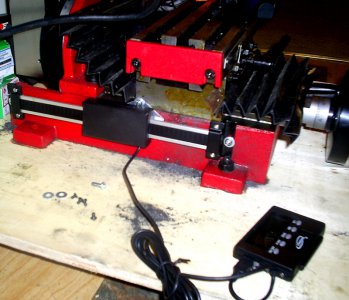

Setting up a new HF mini mill/drill for a new HMS. I took a chance and ordered three DigiMag remote readouts from Amazon for about $100. Yesterday I mounted the X and Y axis units on the mill, and I am pretty pleased with the results of the install. Still have to get the air spring conversion for the Z, so that DRO will have to wait a bit, but X and Y are working well. Working on the display mount and chip guards today.

Anyone else here using these? Any feedback after actually machining parts?

Tom

Anyone else here using these? Any feedback after actually machining parts?

Tom