- Joined

- Mar 25, 2013

- Messages

- 4,617

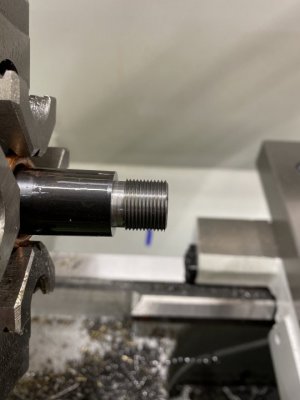

I am not following this? Are you talking for internal threads?I’ve played with it. I mentioned earlier using an internal boring bar and the spindle in reverse. That way the tool forces aren’t lifting the carriage assembly, and I can see the tool. Makes me feel better.