- Joined

- Oct 4, 2020

- Messages

- 484

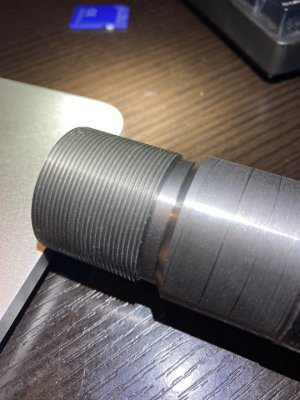

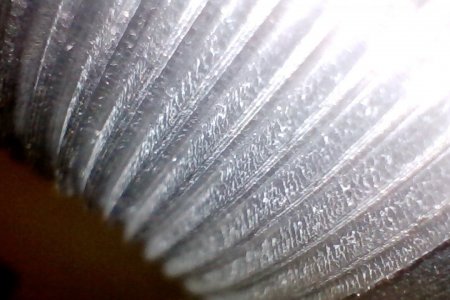

New PM1440GT - My first real lathe. My metal working education is 5 years of Abom79 and This Old Tony, and a week long precision rifle course in Gordy Gritters shop.

I am using the following carbide insert https://www.mscdirect.com/product/details/05765631?rItem=05765631 (Recommended by Gordy) and am practicing to thread barrels. I am using (allegedly) 416 stainless bar I got on ebay.

I am confident that my tool height is correct.

Cut is flooded with dark cutting oil.

Speed is slow, 100rpm-ish

Compound @ 29.5

Cuts are shallow, 5 thou max, last cuts 1-2

All passes are done by advancing the compound, except for the last pass, I push the crossslide in a though.

I did lick the top of these threads with a file because they were sharp as a cats claw.

Because I am new at this I don't know what I don't know and am open to questions, feedback, etc etc. Let me have it.

I am using the following carbide insert https://www.mscdirect.com/product/details/05765631?rItem=05765631 (Recommended by Gordy) and am practicing to thread barrels. I am using (allegedly) 416 stainless bar I got on ebay.

I am confident that my tool height is correct.

Cut is flooded with dark cutting oil.

Speed is slow, 100rpm-ish

Compound @ 29.5

Cuts are shallow, 5 thou max, last cuts 1-2

All passes are done by advancing the compound, except for the last pass, I push the crossslide in a though.

I did lick the top of these threads with a file because they were sharp as a cats claw.

Because I am new at this I don't know what I don't know and am open to questions, feedback, etc etc. Let me have it.