-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

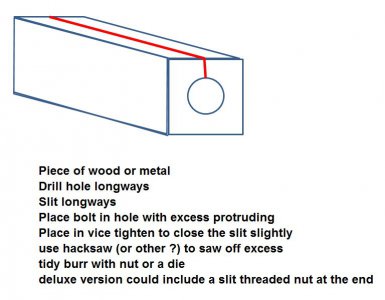

How Do You Cut Screws To The Proper Length?

- Thread starter rwm

- Start date

I cut a large number of screws and bolts. The small ones I cut with an electrical crimping tool and then clean up on a grinder or belt sander. The larger ones (1/4" and up) I band saw off, grind or sand the end to desired shape then use a fine wire brush wheel on a bench grinder to clean up the threads. This leaves the threads so clean that the use of a nut or die to straighten them is not needed.

Lee

Lee

- Joined

- Jul 20, 2014

- Messages

- 1,386

This info here is all good. Some bolts, screws, etc.. are not made in short lengths.

i.e. SHCS (allen bolts). I need some 10 mm SHCS in really short lengths but they are not made

so the ideas and methods here will come in handy. Thanks.

i.e. SHCS (allen bolts). I need some 10 mm SHCS in really short lengths but they are not made

so the ideas and methods here will come in handy. Thanks.

- Joined

- Jan 22, 2011

- Messages

- 8,031

I used to make a fair quantity of 5/16-24 x 1/4 SHCS for a customer. I simply made a plate with a row of tapped holes and screwed them through it snugly and put this plate on parallels in the mill vise and mowed them just above flush. Using a carbide EM at high speed, there wasn't much of a burr, and I twirled them on a wire wheel held by a hex key. Could do a couple of hundred in less than an hour.

I guess the few machine screws I cut I use the old wire stripper/screw shear. It's not often I need it.

I guess the few machine screws I cut I use the old wire stripper/screw shear. It's not often I need it.

- Joined

- Mar 25, 2013

- Messages

- 4,617

After contemplating the discussions above I came up with this quick and dirty jig to be used on my vertical bandsaw.

I just insert the screw to the proper length (I can use a jamb nut to prevent it from turning) and set the rip fence for exactly 2". The threaded plate is CRS with holes for 4-40, 8-32, 10-32 and 1/4-20.

I am still toying with the idea of a dedicated chopsaw type machine with an abrasive blade. That might reduce the need for finishing the end of the cut screw. This works well for now.

R

I just insert the screw to the proper length (I can use a jamb nut to prevent it from turning) and set the rip fence for exactly 2". The threaded plate is CRS with holes for 4-40, 8-32, 10-32 and 1/4-20.

I am still toying with the idea of a dedicated chopsaw type machine with an abrasive blade. That might reduce the need for finishing the end of the cut screw. This works well for now.

R

- Joined

- Feb 9, 2015

- Messages

- 99

This thread got me to thinking.anic: This HF tool might have a use after all. http://www.harborfreight.com/2-in-mini-bench-top-cut-off-saw-61900.html A 2" cutoff wheel some 1" angle drilled and taped for te screws. If you cut alot of screws.

==========================================================================================

I have one of those saws. The blade that comes with it, works well with soft metals, I use it for 5/16" brass rod, when making jets for carbs.. Also got a thicker blade for cutting screwdriver slots in the jets. Runs to fast for steel. I did buy some 2" cut-off wheels. HF does not sell them though. Found them on E-bay. They were even recommended for the HF saw, among others.

If you use the wheels for anything above 1/4, that is steel, "Bring Your Lunch". You have to go slow, due to a lack of power from the motor. You cannot put much pressure on the wheel. I used it to split a 7mm threading die. The material was about 3/8" wide and about 3/16" thick. Took me all of 15+ minutes to get through it. Glad I had only one to do. The saw does what it was designed to do. Just not as much as you might like it to. --- John

====================================================

- Joined

- Nov 27, 2012

- Messages

- 7,857

Usually I only need to remove short lengths from screws so I just use a simple strip of flat bar with holes tapped in it. I screw in the screw & grind down what I need on a belt sander or grinder.

The last one I made was alumn (figured it might help with heatsinking). It's pretty chewed up now but it's easy for me to make new ones as I have the DRO coordinates written down.

1 side goes from 0-80 to 5/16"-24. The other side goes from M2.5x.45 to M10x1.5

The last one I made was alumn (figured it might help with heatsinking). It's pretty chewed up now but it's easy for me to make new ones as I have the DRO coordinates written down.

1 side goes from 0-80 to 5/16"-24. The other side goes from M2.5x.45 to M10x1.5