- Joined

- Mar 26, 2018

- Messages

- 8,408

Bob,I have never been a sucker for buying top rated tools at top pricing with a "best" reputation due to the name on it, when there are equal quality vintage tools available at MUCH lower pricing...

I would agree, I do have one exception though.

I had to have Starrett Tap wrenches. 91A and 91B. Surprisingly though, I had to clean and polish the action to get that smooth operation. There was grit and burrs on both when I opened them when brand new.

I was sick of the taps coming loose. Once you have used one of these, there is no going back to the dark side. IMHO

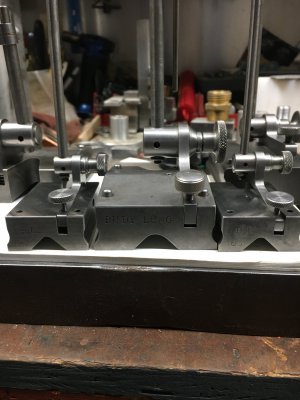

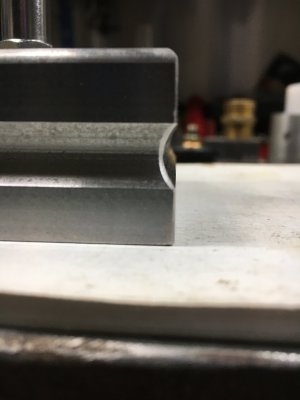

91B Tap Wrench

The Starrett 91 Tap Wrench is strong and well proportioned. It is nicely finished and the gripping surface is properly tempered. It will firmly hold square or round shanks. It is plunger operated by knurled sleeve, the spring inside the sleeve causes plunger to back off when pressure is removed...