- Joined

- Feb 1, 2015

- Messages

- 9,621

Sorry, I can't count today.What?

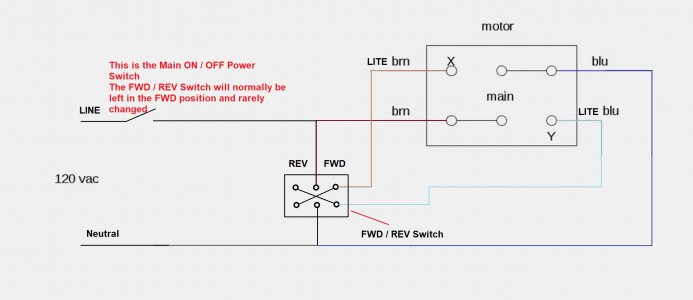

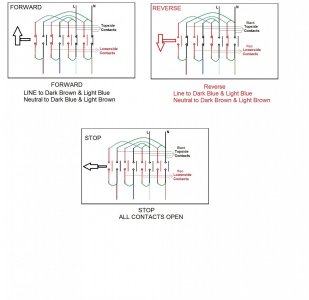

Six wires plus ground. However, the start and run capacitors are external to the motor, hence extra wires. U1, U2, V1, & W2 run to the switch and W1 & V2 go to the capacitors. Yg is the ground wire.

Six wires plus ground. However, the start and run capacitors are external to the motor, hence extra wires. U1, U2, V1, & W2 run to the switch and W1 & V2 go to the capacitors. Yg is the ground wire.