- Joined

- Apr 30, 2015

- Messages

- 11,328

Agreed, I think entirely too many things are thrown away when they could be fixed

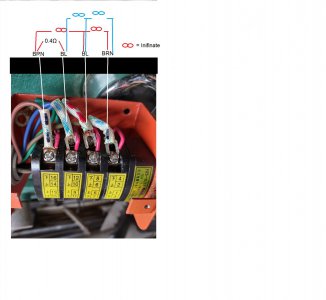

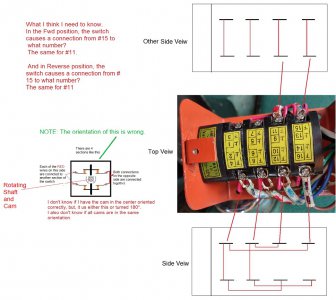

The switch is of the "Baomain" type which is (I think) symmetrical in the contact closures

I'll post a truth table for it- give me a few minutes

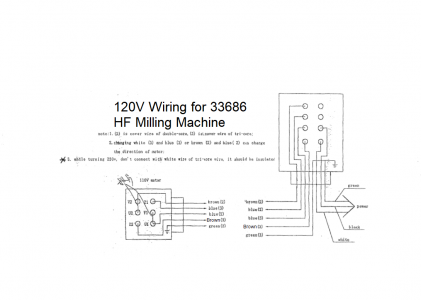

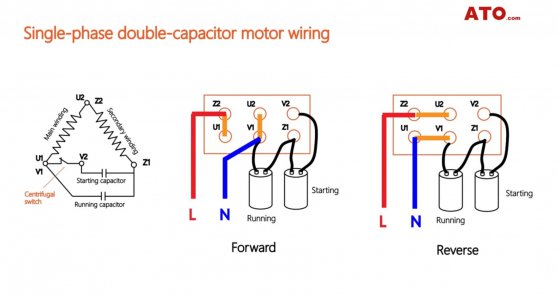

The motor reverses by swapping one pair of wires; the switch does that and also does the "on/off" function for power

Here is a typical truth table:

The switch is of the "Baomain" type which is (I think) symmetrical in the contact closures

I'll post a truth table for it- give me a few minutes

The motor reverses by swapping one pair of wires; the switch does that and also does the "on/off" function for power

Here is a typical truth table:

Attachments

Last edited: