- Joined

- Sep 18, 2023

- Messages

- 28

I have cut a rectangular steel tube as close to having true corners as I can manage with the tools I have. Thanks to people who provided help on an earlier thread about this!

What I have is probably good enough for my application, but I’m enjoying learning, so I’d like to further refine a bit more.

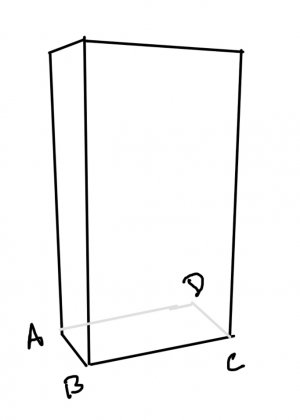

When I place the cut tube on a glass sheet, it rocks diagonally from one set of corners and not the other. Here is a picture to illustrate:

It rocks back and forth with the O points alternately touching. The X points don’t rock.

I’m having a tough time visualizing where I’d need to remove material to make it not rock.

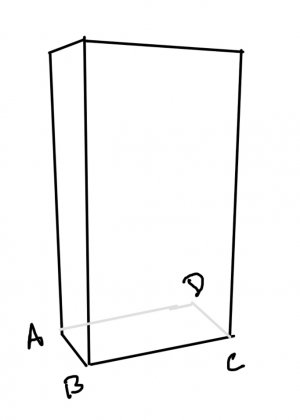

To make it easier to answer, here is a diagram. I could remove material at the points, or on parts of a line. So you could say: file at point X or remove material on the line XY closer to Y, for example.

Just to say it, I know that flattening it might leave it not square/could have a tilt.

What I have is probably good enough for my application, but I’m enjoying learning, so I’d like to further refine a bit more.

When I place the cut tube on a glass sheet, it rocks diagonally from one set of corners and not the other. Here is a picture to illustrate:

It rocks back and forth with the O points alternately touching. The X points don’t rock.

I’m having a tough time visualizing where I’d need to remove material to make it not rock.

To make it easier to answer, here is a diagram. I could remove material at the points, or on parts of a line. So you could say: file at point X or remove material on the line XY closer to Y, for example.

Just to say it, I know that flattening it might leave it not square/could have a tilt.