- Joined

- Jan 2, 2014

- Messages

- 8,853

I just reviewed. The power supply is 12V at 10 amps.

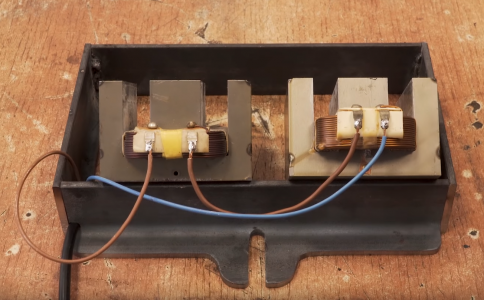

Note too that in the video he wired the two coils in series:

So IF his coils were like mine (that I mentioned in post #14) and were around 1 ohm each.

He would have 12V across 2 ohms or about 6A thru the coils.

(His power supply could provide 10A, but he only was using 6A.)

-brino