- Joined

- Feb 4, 2021

- Messages

- 12

Found this one on Amazon

Sent from my SM-N950U using Tapatalk

Sent from my SM-N950U using Tapatalk

MarkOK I see, switch is probably a lost cause. I can suggest some switches from Amazon and show how to wire it. I would plan on running this machine on 220/240 volts, because of the current draw

-Mark

OR if you want to just get it running quickly in one direction with a simple toggle switch we could do that instead. Reverse is less useful on a mill than a lathe

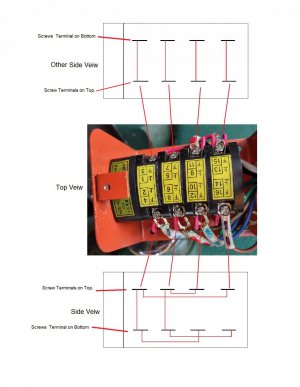

Maybe not clear in my presentation, but I have Pictures and a drawing, very confident I can get that part right.Yep. I've seen it before. Not very clear how the red jumpers are wired.

Sent from my SM-N950U using Tapatalk

brady, I have the red jumper positions drawn, the problem is, what position do the 4 cams go in.Yep. I've seen it before. Not very clear how the red jumpers are wired.

Sent from my SM-N950U using Tapatalk

I didn't note your post before my last post, so here is the way the RED jumpers are wired on the switch.I have a mill and the switch is in pieces with wires removed. Can anyone with this mill send me a pic of the switch and where the wires are connected? Also detail on the jumper wire positions. To clarify... 16 poles on the switch. Forward off reverse. 2 capacitor motor. Thanks!

Sent from my SM-N950U using Tapatalk

First thing to check, does your switch have more that the original 3 positions FWD/OFF/REV?Mark

I have the same mill and my switch just went south. i would be interested in your input on wiring into a single switch? Never has used reverse and dont expect to. My assumption is to only wire one side but would prefer some expert advise to avoid a motor replacement. Any help is appreciated.