- Joined

- Aug 12, 2013

- Messages

- 858

Well looks like you might have found the culprit. Now see if Grizzly will send you a new one.

Ohh... and go buy a new dial indicator. Even a $15 one. You NEED one to tram your mill.

Post a picture of your motor. Most motors like this have a TEFC (Totally Enclosed Fan Cooled) motor... where the fan is under a cowling on the back which blows are over the outside of the motor. Unusual to find a motor that is a Totally Enclosed Non-Ventilated (TENV) motor on a mill, which is what it seems you have, since I suspect it would overheat during extended milling, especially when running with a VFD.

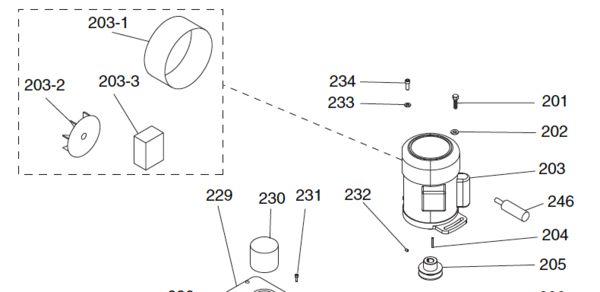

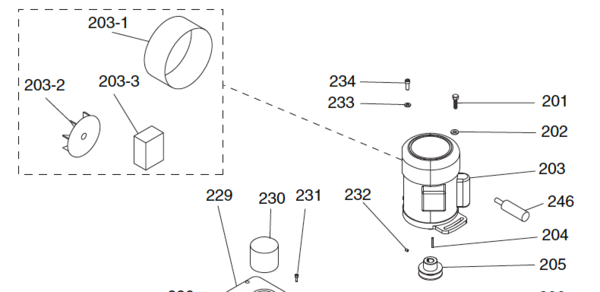

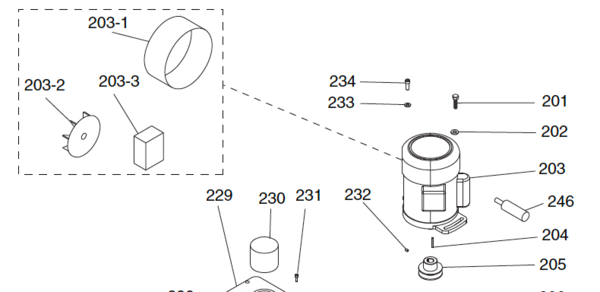

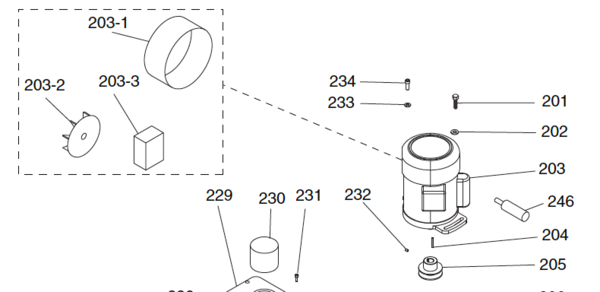

EDIT: looking at your picture in the first post, that looks like a TEFC to me. That black cowl on the top of the motor should cover the fan, and should be attached to the motor by three little screws.

Ohh... and go buy a new dial indicator. Even a $15 one. You NEED one to tram your mill.

Post a picture of your motor. Most motors like this have a TEFC (Totally Enclosed Fan Cooled) motor... where the fan is under a cowling on the back which blows are over the outside of the motor. Unusual to find a motor that is a Totally Enclosed Non-Ventilated (TENV) motor on a mill, which is what it seems you have, since I suspect it would overheat during extended milling, especially when running with a VFD.

EDIT: looking at your picture in the first post, that looks like a TEFC to me. That black cowl on the top of the motor should cover the fan, and should be attached to the motor by three little screws.

Last edited: