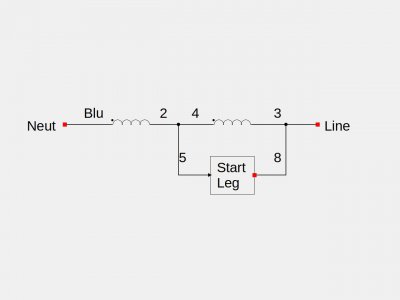

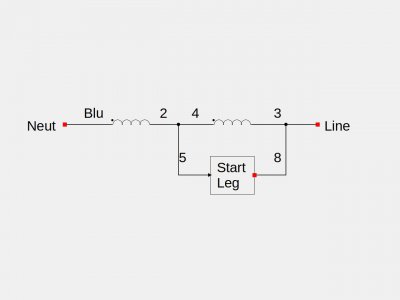

So I drew it out and it looks like this (below): I would say it was wired for 220/240 by the previous owner

It may seem to run ok on 120 volts but it may not be. I'm guessing it's staying in start mode and not getting up to

the proper speed to kick out the start circuit; not developing full power

For 120 volts then we would expect Blu, 4, and 5 tied together and 2, 3, and 8 tied together- all elements in parallel

HOWEVER- something tells me that isn't correct either, since it doesn't match the dataplate (no P2 wire) and the polarity

of the two run windings is in question. The Blu wire may be the leg with the thermal button in series.

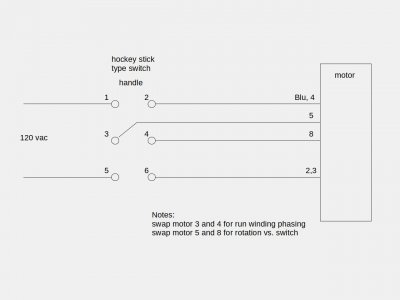

It would be wise to do a pair of run tests, one run winding at a time

to verify the polarity:

Test 1: Disconnect 2. Move neutral to 4 and 5; connect hot to 3 and 8. Apply power; note rotation.

Test 2: Disconnect 3 and 4. Connect neutral to Blue and 5. Connect hot to 2 and 8. Apply power and note rotation.

Should have same rotation direction in both cases