- Joined

- Mar 25, 2013

- Messages

- 4,626

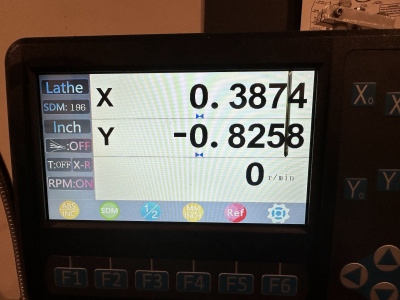

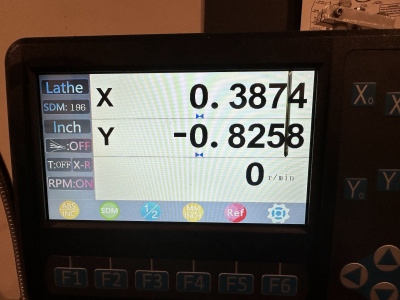

The display only has options to display 4 or 5 decimals. I set it to 4 but I know from experience that I will need to block out or obscure the last digit.

The line is just dry erase. I will probably cover the digits with tape. Its a shame you can't select 3 decimals like my other DRO.

Pontiac- I don't see any com port. But maybe internally? There must be one.

The line is just dry erase. I will probably cover the digits with tape. Its a shame you can't select 3 decimals like my other DRO.

Pontiac- I don't see any com port. But maybe internally? There must be one.