- Joined

- Mar 25, 2013

- Messages

- 4,615

I just reset the ride height using a .5mm shim and then pulled out the shim. I see no difference. I still get almost a .002" error on my 123 block.

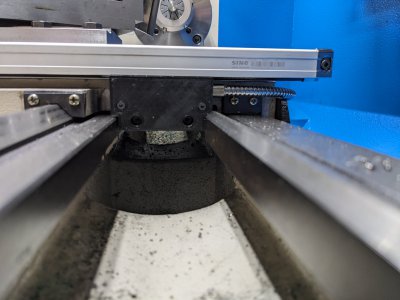

Yeah, I've got gib screws, carriage lock, compound lock all in the way, plus a close back splash that limits travel. I only have 135mm X travel but when you use a 150mm glass scale and add in the longer read head it gets pretty long.

Wobbly- can you post a link to the glass scale you used?

I'm looking at some glass scales now. Some might fit. Unfortunately Ditron seems to make the most compact! I hate to spend any more money there!

Yeah, I've got gib screws, carriage lock, compound lock all in the way, plus a close back splash that limits travel. I only have 135mm X travel but when you use a 150mm glass scale and add in the longer read head it gets pretty long.

Wobbly- can you post a link to the glass scale you used?

I'm looking at some glass scales now. Some might fit. Unfortunately Ditron seems to make the most compact! I hate to spend any more money there!

Last edited: