This statement could be telling (Every time the bit snapped, it always did so upon entering the lower flange.)

You could be right. The farther the bit extends, the worse the play gets. It's traveling pretty far to reach the lower flange. It's 0.200" top to bottom, after going through 0.060" + 0.080" + air gap. It's close to 3/8". I should check the quill for slop, and see if there is any adjustment I can make to tighten things up. I do have a suspicion that something could be off.

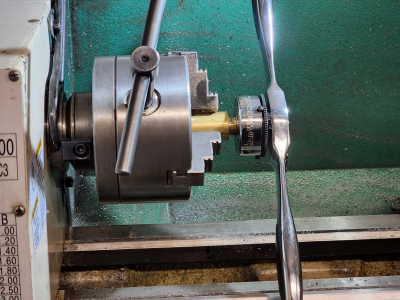

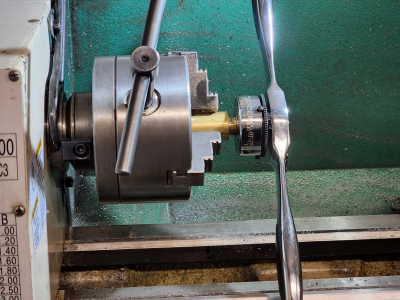

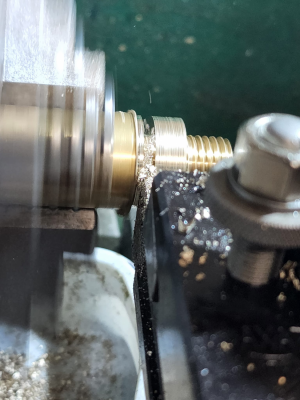

At least things should be better on the lathe side of this operation. I got the ISCAR MT4 ER32 and had to face my first problem. It was set up for through coolant, and while it would be useful to be able to extend a small diameter part all the way through, it would be hard to knock out without a beater backer. I ordered an off-the-shelf beater backer from McMaster-Carr, and when it came in, I got an M6 instead of an M16, because I'm stupid.

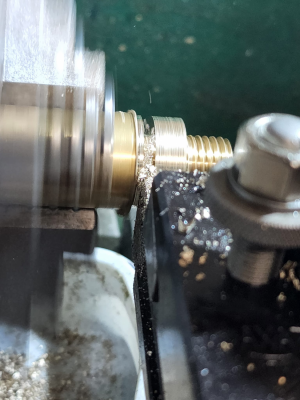

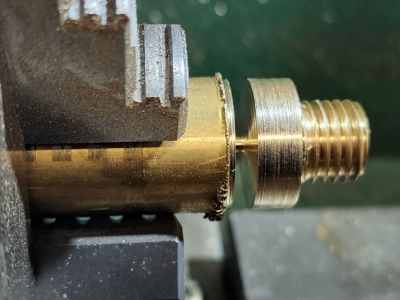

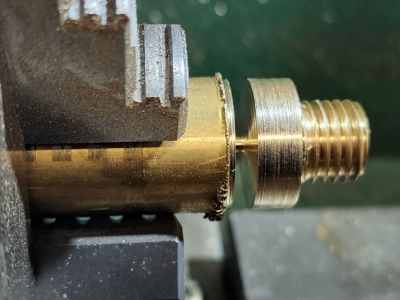

So I makeded one.

I cheated and just smoothed the end on a belt grinder. Then I whacked it in, and set up the tenths indicator. This is WAY better than the Chinese one I had before. It's still a lot of TIR compared to what I could achieve in theory, but I went from 0.0160" to something like 0.0004". Sometimes, spending money on good stuff actually rewards you.

I did enhance that image a little in the GIMP, but I actually recorded several Super Slo-Mo videos with my phone, and the worst I saw was 0.0008" TIR, and it was only that bad because the needle reached that far once in 18 seconds.

For a Chinese lathe and Chinese collets, I'm going to call this a gigantic improvement, and a huge win. I could probably get it even better if I shelled out for Rego-Fix or Techniks collets, but I might not do any better at all. It's a piece of "tight tolerance" O1 drill rod from McMaster-Porn, and it's just a chunk lopped off the end in a bandsaw. It's obviously not perfect, because when I go near the cut end, the needle goes all to hell. My lathe may not be the most accurate, but it's not THAT bad.

Anyway, it's the lathe I own. I can't afford to shell out for a Taig or a Sherline or whatever right now. I have to do this with what I have, or I can't afford to do this at all. They used to make clocks by hand filing the teeth by eyeball, and I think it will all be totally fine in the end. I think I can, I think I can, I think I can.

No, I still don't have the damn mill leveled yet. I'm close. I'm taking a break to let the levels settle. Yeah, the levels. It has nothing to do with the scotch I'm drinking.

Public Service Announcement: DO NOT OPERATE MACHINERY WHILE UNDER THE AFFLUENCE OF INKAHOL. YOU COULD END UP CALLING AN AMBULANCE TO TAKE YOU TO THE ER TO HAVE PARTS SEWN BACK ON, BECAUSE YOU WERE TOO DRUNK TO DRIVE THERE YOURSELF, YOU ALCOHOLIC LOSER!

But tweaking some wrenches by hand, and checking some bubbles. That's fine. Enjoy your vacation!