- Joined

- Feb 1, 2014

- Messages

- 339

Update!

Took the lathe apart to move it into the new shop.

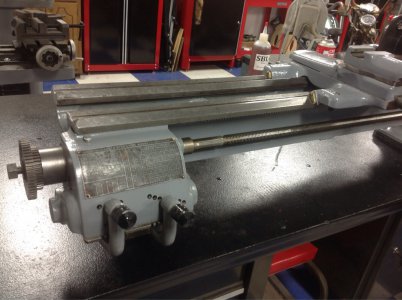

In the interim, a good friend passed along another 9A that he saved from the scrapper! The bed is a 3 1/2'. The headstock is full of rust and has a flat belt pulley cone. The motor and drive are rusted up pretty good too. It didn't have a tail stock.

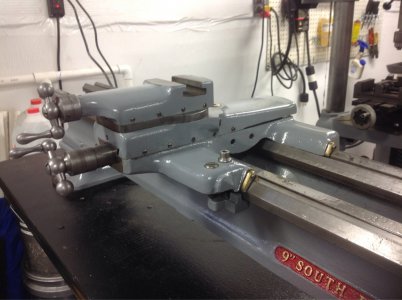

The bed was coated in rust and grime. The ways cleaned up real well and it has some nice flaking visible! My "old" 9A's apron did not have the compound feed, but the "new" one does!

So, now the question is, do I take the best of both and make one, or do I just make two?

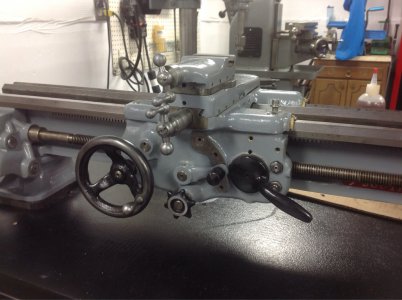

I'm thinking that I could use the "old" head, tail stock and drive on the "new" bed along with the "new" gearbox and compound.

I'm thinking the most critical thing is to keep the bed and compound together. The rest should be ok to swap around right?

So far, I have the "new" gearbox disassembled... I am going to go through everything one section at a time, and then decide how it should go together...

Sent from my iPad using Tapatalk

Took the lathe apart to move it into the new shop.

In the interim, a good friend passed along another 9A that he saved from the scrapper! The bed is a 3 1/2'. The headstock is full of rust and has a flat belt pulley cone. The motor and drive are rusted up pretty good too. It didn't have a tail stock.

The bed was coated in rust and grime. The ways cleaned up real well and it has some nice flaking visible! My "old" 9A's apron did not have the compound feed, but the "new" one does!

So, now the question is, do I take the best of both and make one, or do I just make two?

I'm thinking that I could use the "old" head, tail stock and drive on the "new" bed along with the "new" gearbox and compound.

I'm thinking the most critical thing is to keep the bed and compound together. The rest should be ok to swap around right?

So far, I have the "new" gearbox disassembled... I am going to go through everything one section at a time, and then decide how it should go together...

Sent from my iPad using Tapatalk